Secure Remote Access to Industrial Robots

A Robustel Application Example

Application Example – Fast Facts

Industry

Industrial IoT, Factory automation, high-throughput manufacturing, robotic integration

Product(s)

EG5120 Edge Computing Gateway; RCMS (RobustLink, RobustVPN)

Challenges

Industrial robots are shipped as turnkey systems, often with vision, safety, and tooling built in. Once they’re installed on a customer site, the integrator usually loses direct access. When a robot stops, support teams can’t see controller data or alarm history without being physically at the panel. Production waits.

Expected Outcomes

Give every industrial robot a managed, secure communications path so support engineers can view live status, pull diagnostic information, and guide recovery remotely. Reduce downtime and protect service margins without fighting plant IT for access.

When an industrial robot stops, production stops

On a modern line, the robot isn’t just welding, picking, or placing. It’s feeding the next station, keeping takt time stable, and protecting quality. A stalled robot can back up work-in-progress, force manual handling, and throw a shift off schedule.

Here’s the problem: once the robot is handed over, the integrator usually can’t see inside it anymore. The controller sits on a protected production network. The safety PLC, vision system, and gripper logic are all inside the guarded cell. When the plant calls and says “the robot is down,” the integrator is effectively blind. They don’t know if it’s a safety trip, a camera misread, a torque limit, or operator intervention.

By installing a Robustel EG5120 industrial edge gateway inside the robot’s control cabinet before delivery, the integrator keeps a secure, auditable path back to that robot in the field. Support becomes immediate and informed, not “we’ll be there when we can.”

Business Challenges

Both integrators and plant operators feel pain in the same places:

- Downtime burns money fast. A single robot can block an entire cell. If it’s upstream in the process, stoppage cascades. If it’s downstream, pallets stack up. Either way, output and OEE targets slip.

- Remote access is political. Many plants do not allow third parties onto their production network. IT teams are rightly cautious about inbound VPN tunnels. The result is: no remote visibility for the people who are contractually responsible for keeping that robot running.

- Support starts from zero context. The first call is “the robot’s faulted.” But without seeing the controller, support can’t tell if it’s a recoverable condition or a mechanical problem that truly needs someone on site. So you roll a field engineer as insurance.

- No record of what actually happened. Local operators might bypass an interlock or tweak motion just to get parts moving again. Weeks later, if there’s a quality concern or safety review, neither side can prove what changed and when.

That’s bad for uptime, bad for warranty cost, and bad for customer trust.

Solution Overview

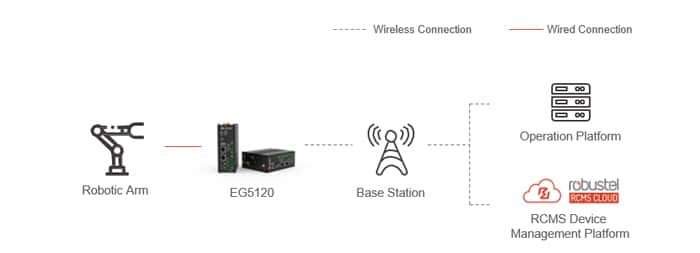

The industrial robot, and its guarded cell, ships with a Robustel EG5120 already in the cabinet. That gateway becomes the secure bridge between the robot’s control stack on the floor and the support team offsite.

One template, everywhere you ship Because the EG5120 and its RCMS profile are part of the standard build, every robot leaves the factory “service ready.” You’re not improvising access for each new plant. You’re delivering robots with a built-in support model.

Direct connection to the robot controller and safety systems The EG5120 ties into the robot controller, safety PLC, vision system, and HMI using Ethernet and, where relevant, serial interfaces such as RS-232 or RS-485. That means live alarms, status bits, counters, and cycle data can be viewed without physically standing at the cabinet.

A controlled uplink out of the plant The EG5120 provides its own wide-area connection using cellular (4G/LTE, 5G where available) or a tightly scoped Ethernet uplink. This gives the integrator an outbound, encrypted channel that does not require the plant to open broad access to its OT network.

Secure remote support instead of blind troubleshooting Through the EG5120, support staff can establish an encrypted session, review the robot’s fault state, confirm what actually tripped, and walk local maintenance through safe recovery. Access can be time-limited and scoped to that one robot or cell so IT and safety teams stay comfortable.

Fleet-level oversight in RCMS All deployed EG5120 units report into RCMS. From there, the integrator can see which robots are reachable, which sites are showing repeated alarms, and which installations are drifting from approved configuration or firmware. That turns support from reactive firefighting into active supervision of the installed base.

Expected Customer Outcomes

What success looks like for the customer and the robot supplier

For the integrator / robot supplier:

- You don’t waste time sending people on-site just to discover a recoverable safety latch or recoverable vision error.

- You can meet response-time promises because you’re not negotiating network access during the crisis.

- You can prove the condition of the robot when you touched it, and prove the guidance you gave, which protects warranty position.

- You create a repeatable after-sales service model instead of “best effort” support.

For the plant:

- The robot comes back online faster. Minor stoppages don’t turn into half-shift outages.

- Operators get expert support in minutes, not hours, without improvising unsafe overrides just to get output moving.

- There’s traceability. You can look back at what faulted, what changed, and when normal operation resumed.

In plain terms: the robot is no longer an isolated black box. It becomes an asset with live support behind it.

Featured Products

Robustel EG5120 Gateway

RCMS Cloud Device Management

Talk to an Expert

If you build or support industrial robots, you shouldn’t lose visibility the moment they’re commissioned.

Talk to us about delivering every robot with secure remote access, diagnosable faults, and a support model you can stand behind — no site visit required.