Secure 4G/LTE Remote Access to Hospital and Medical Equipment Using the Robustel R1511

A Robustel Application Example

Application Example – Fast Facts

Industry

Smart Cities, Healthcare, medical equipment service and maintenance

Product(s)

Robustel R1511 4G/LTE Router; RCMS (RobustLink, RobustVPN)

Challenges

Hospitals and clinics rely on complex diagnostic and treatment equipment that must stay available, calibrated, and patched, but many sites lack safe, controlled remote access to these devices. Service teams are often forced to send engineers on site for issues that could be diagnosed or fixed remotely, increasing cost, delaying repairs, and disrupting clinical schedules.

Expected Outcomes

Give medical equipment manufacturers and service providers a secure, standard way to reach installed devices over 4G/LTE without touching hospital core IT networks. Reduce unnecessary site visits, shorten time to diagnose faults, and keep modalities available more of the time, while meeting strict expectations around safety, data separation, and change control.

Keeping critical medical equipment online without living on-site

Modern hospitals depend on connected equipment: imaging systems, analysers, infusion devices, and specialist treatment platforms that all need regular updates, calibration, and support. When one of these systems is unavailable, whole lists of patients can be delayed, and clinicians lose confidence in the technology they rely on. At the same time, hospital IT teams are rightly cautious about opening inbound access through their core networks for external vendors and service providers.

Service organisations are caught in the middle. They need enough access to troubleshoot quickly and safely, but they also need to respect the security posture and workflow of every hospital and clinic they support. This is where a dedicated, independent connectivity path to the device can change the model. By embedding a small industrial router like the R1511 alongside the equipment, service teams can reach assets in the field in a controlled, audited way, without pushing risk onto hospital IT.

Business Challenges

Many medical equipment manufacturers and service providers started with a “travel first” model: when something goes wrong, send an engineer. As installed bases grow and devices spread across regions, that model becomes expensive, slow, and hard to scale. This use case focuses on the operational barriers that made remote maintenance difficult before a standard connectivity layer was in place.

- Limited remote visibility: Without a dedicated connection into each device, service teams often rely on phone calls, emailed screenshots, or log exports from hospital staff. That makes it hard to understand whether an issue is hardware, configuration, or environment. Root cause analysis can drag on, and the safest option becomes dispatching an engineer even when the underlying problem may be minor.

- Dependence on hospital networks and policies: Gaining remote access via the hospital’s own network requires firewall changes, VPN accounts, and approvals from security and IT teams that are already busy. Different sites have different policies, tools, and comfort levels with third-party access, which slows deployments and upgrades. In some cases, remote support is blocked entirely, forcing all maintenance into on-site visits, regardless of severity.

- Cost and delay of on-site interventions: Travel, access coordination, and physical presence in clinical areas all add time and cost. Engineers may spend hours reaching a site only to discover a configuration issue that could have been fixed remotely in minutes. This not only increases service costs but also prolongs downtime windows for equipment that clinicians and patients are waiting on.

Solution Overview

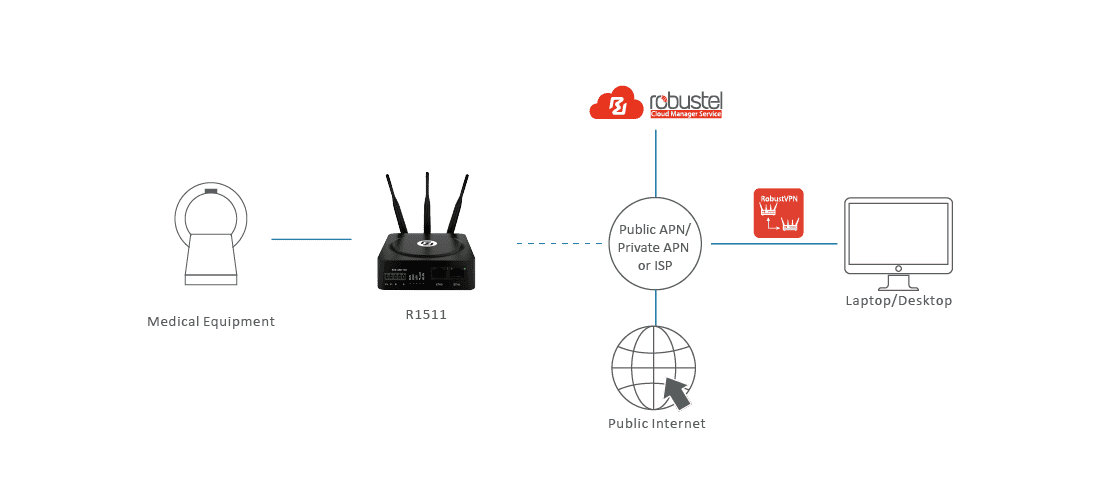

To break this pattern, medical equipment vendors and service organisations can embed a Robustel R1511 industrial router inside or alongside each supported device. The R1511 uses 4G/LTE to establish an outbound-only, encrypted connection to the service provider’s environment. From there, authorised engineers can access the device using their usual tools, without the hospital needing to open inbound ports or reconfigure their internal network.

The R1511 connects via Ethernet (or, where appropriate, serial-to-IP bridging) to the medical equipment or its local service port. It is preconfigured with a standard template so every deployed unit behaves the same way: a secure tunnel out, strict firewalling in, and clear separation between the hospital’s clinical network and the vendor’s maintenance path. Fleet-wide monitoring and configuration can be handled via RCMS if the organisation chooses to adopt cloud management, allowing central teams to see which devices are online, what firmware routers are running, and where connectivity issues exist.

- Dedicated maintenance path: The R1511 gives each covered device its own cellular maintenance channel, separate from hospital LANs. This makes it easier to gain approval, as risk is clearly bounded and traffic can be tightly controlled.

- Consistent access model across sites: With a standard router and configuration profile, engineers connect the same way whether the device is in a major teaching hospital or a small clinic. That consistency simplifies training, documentation, and support workflows.

- Secure, outbound-only connectivity: The router initiates connections out to the service environment, avoiding inbound exposure from the internet. VPN and firewall controls ensure only authorised management traffic reaches the device, supporting the security expectations of healthcare IT and compliance teams.

- Compact, equipment-friendly design: The small footprint and industrial design of the R1511 make it easy to mount inside racks, cabinets, or equipment housings, using existing power and requiring minimal changes to site infrastructure.

Expected Customer Outcomes

What success looks like for the key stakeholders:

- Service leaders and equipment manufacturers – Reduced cost per intervention: Remote access through the R1511 lets central teams diagnose and often resolve issues without dispatching an engineer. Site visits are reserved for cases where hands-on work is truly required, improving margins and allowing the same team to support more installed devices.

- Hospital IT and security teams – Clear network separation and control: Because the maintenance path is over cellular and controlled by the vendor, hospital IT does not have to open their internal network to third parties. They gain assurance that clinical systems remain segmented, while still benefiting from faster support when equipment misbehaves.

- Clinical operations managers – Shorter disruption windows: Downtime for imaging, monitoring, or treatment equipment can be reduced when engineers can connect immediately rather than waiting for travel. Faster diagnosis means quicker decisions on whether equipment can be returned to service, rescheduled, or swapped, helping protect patient flow and appointment schedules.

- Field engineers – Better prepared site visits: When an on-site visit is needed, engineers arrive with a clearer picture of what is wrong because they have already seen logs and system behaviour over the R1511 link. This increases the likelihood of fixing issues on the first visit, reducing returns and rework.

- Installation partners and biomedical technicians – Simple, repeatable installs: A standard pattern for mounting and wiring the R1511 reduces complexity during equipment deployment. Once power and a basic connection are in place, the rest of the onboarding can be completed remotely, limiting the amount of specialised networking work needed on site.

Featured Products

Robustel R1511 4G/LTE Router

RCMS Cloud Device Management

Talk to an Expert

If you build or support medical equipment and want a safer, more scalable way to reach devices in hospitals and clinics, we can help you design a connectivity pattern that works for both your service team and your customers’ IT departments.

Talk to one of our specialists about using the R1511 as a standard remote maintenance platform for your installed base.