Keeping a national Automated Meter Reading (AMR) rollout online:

How Robustel & Energobit modernised legacy meter communications with the M1000.

Case Study – Fast Facts

Location

Romania

Industry

Energy & Utilities

Product(s)

- M1000 (Note: Product now replaced by M1000-MP)

End Customer

Energobit – https://www.energobit.com/

Energobit is a Romanian engineering and solutions provider working across electricity management, metering systems, and power infrastructure projects. The company delivers turnkey systems that combine field hardware, protection and control equipment, and metering software for utilities and large industrial clients. Its projects are often subject to strict uptime, accuracy, and compliance expectations, particularly when serving national-level oil and gas operations.

Challenges

Energobit was contracted to deliver an AMR system to monitor energy usage at oil and gas pipeline booster stations distributed across both urban and remote areas. The meters in the field exposed only RS-485 interfaces, while the existing AMR head-end expected to talk to a specific vendor’s GPRS modem using a proprietary communication mechanism. Standard GPRS modems could not stay reliably online under frequent polling, and none of the alternatives tested were accepted by the central AMR software.

Results

By implementing the original modem’s protocol in the M1000 and supporting RS-232/RS-485 selection in software, Energobit deployed thousands of modems that worked seamlessly with the legacy AMR platform. The new solution delivered stable, “always aware” communications across a challenging geography, with no reported device failures over the first two years in service and significantly reduced integration risk for future expansions.

Modernising AMR communications without changing the head-end

Energobit was asked to provide an AMR system to track power consumption at pipeline booster stations for a major oil and gas operator. The sites were scattered across cities, small towns, rural plains, hills, and forested areas, making wired connectivity impractical and pushing the design towards wide-area cellular communications.

The existing AMR platform, however, was tightly coupled to a specific vendor’s GPRS modem and was never designed to accept third-party devices. At the same time, the meters already installed in the field only supported RS-485, and the operational requirement was for frequent polling and near real-time visibility of energy usage. Energobit needed a way to introduce a modern industrial modem into this environment without forcing any change to the head-end software.

Business Challenges

1. Keeping AMR links “always on” under heavy polling

The AMR platform was designed to poll remote meters frequently so that operators could monitor power usage and detect anomalies quickly. This required the GPRS modem at each site to stay registered on the network, recover from any drop, and resume communication without manual intervention. The originally selected AT-command modem behaved passively, dropping offline and staying disconnected until polled in very specific ways. Under real operating conditions, this meant missed readings and intermittent visibility.

Day to day, that behaviour translated into a support burden and operational risk. Control room staff could not trust that a silent meter was genuinely idle rather than just disconnected. Engineers spent time chasing communication faults instead of focusing on network performance. For a national oil and gas operator, this level of uncertainty around data flow was not acceptable.

2. Bridging legacy RS-485 meters to GPRS in harsh environments

Most meters already installed at the booster stations exposed only RS-485 interfaces, which are common in industrial metering but not always available on generic GPRS modems. Energobit needed a modem that could speak RS-485 directly while still supporting RS-232 where required, without adding extra converters or hardware at each site. Environmental conditions around power infrastructure also bring electrical noise and electromagnetic interference, which can disrupt poorly designed communication equipment.

Without the right hardware, cabinets would become cluttered with protocol converters, extra wiring, and additional points of failure. Each extra device increases installation time, power requirements, and the chance of future maintenance visits. For a rollout spanning many sites, this would drive up the cost to serve and make the system harder to support over its lifetime.

3. Making a third-party modem behave like the original device

Perhaps the most difficult challenge was compatibility with the existing AMR head-end. The central software was written to communicate with a specific GPRS modem, using a proprietary communication mechanism and assumptions about how that modem behaved. During testing, alternative modems from several vendors either failed to stay online under the polling profile or were simply not recognised by the head-end. It appeared that only the original vendor’s modem would be accepted.

From a project perspective, this created a serious risk. Continuing with the original modem meant accepting technical limitations and potential supply constraints. Attempting to modify the AMR software would introduce delays, additional cost, and new risks in a system that was already in production. Energobit needed the flexibility of a modern industrial modem, but it had to be “invisible” to the head-end and behave exactly as expected.

Solution Overview

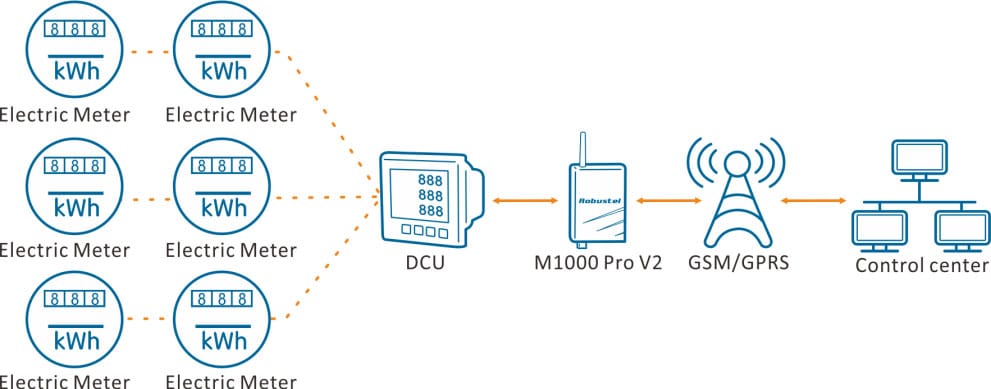

Energobit selected the M1000 industrial GPRS modem and worked closely with Robustel’s engineering team to tailor it to the AMR environment. The M1000 sits inside each field cabinet, connecting directly to legacy meters over RS-485 (or RS-232 where required) and to the mobile network via its built-in cellular modem. It presents itself to the AMR head-end using the same communication mechanism as the original vendor’s device, so the central software can poll meters as before without any changes.

In operation, the modem maintains a stable GPRS session, monitors connectivity, and ensures that polling requests from the AMR server reach the meter reliably. If GPRS coverage is temporarily lost in more remote sections of the pipeline, the modem can fall back to Circuit Switched Data (CSD) when configured, preserving communications where possible. High electromagnetic compatibility design allows the devices to operate reliably in substations and other electrically noisy environments, while software-selectable RS-232/RS-485 simplifies installation and spares holdings for field teams.

Why the customer chose the M1000-MP

- Protocol-level compatibility: Robustel’s engineers reverse engineered the communication mechanism used between the original modem and the AMR software, then implemented the same behaviour in the M1000. This allowed the new modems to slot into the existing system without any changes to the head-end.

- Flexible serial interfaces: The M1000 offers a serial port that can be configured as RS-232 or RS-485 through software. This meant the same hardware could connect to a wide range of meters across the estate, simplifying procurement, spares, and field engineering.

- Industrial design for harsh electrical environments: The modem’s high EMC design and industrial enclosure are well suited to substations and metering cabinets exposed to electrical noise and temperature variation. This reduced the risk of intermittent faults caused by interference.

- Resilient connectivity options: Support for both GPRS and optional CSD fallback meant the communication link could be maintained even in areas with marginal packet data coverage, which is critical for geographically diverse pipeline routes.

- Responsive engineering support: Energobit benefited from close collaboration during development and testing. Having a vendor able to adapt firmware and behaviour quickly enabled the team to meet project timelines despite the constraints of the existing AMR software.

Key Outcomes

With the M1000 in place, the AMR system could operate reliably across a wide and varied geography without rewriting the central software or changing out existing meters.

“These modems are good, but because of the special communication mechanism and settings in existing metering software, it became an impossible mission to make a third party modem compatible with existing systems.” Said by Sarb Mihai, Project Manager of Energobit. “The new solution works faultlessly with the central software and helped us to complete an almost impossible mission, and we are very satisfied with Robustel’s excellent support, they are always in time with high efficiency, it saved time for the project delivery.”

- Stable meter communications: Booster stations now provide consistent meter readings under the required polling profile, reducing blind spots and giving operators confidence in the data they use to manage the network.

- Reduced integration risk: Because the head-end continued to interact with a device that behaved like the original modem, the project avoided major software changes and the associated testing, certification, and rollout effort.

- Simpler field deployment: A single modem model with software-selectable RS-232/RS-485 allowed engineers to standardise cabinet designs and streamline installations across many sites.

- Lower maintenance burden: Reliable hardware and robust EMC performance helped minimise communication-related faults and site visits, freeing engineering time for higher-value work.

- Scalable AMR platform: With a proven modem design that works with both legacy meters and the existing AMR software, future expansions and upgrades can be planned with less uncertainty.

Featured Products

Robustel M1000-MP Modem