Unlocking Energy-Efficient HVAC Performance with IoT Connectivity:

How Robustel & Armstrong Fluid Technology use the R2010 for real-time HVAC insights.

Case Study – Fast Facts

Location

Global

Industry

Smart Cities, Smart Buildings

Product(s)

- R3000

- R3000-Lite

End Customer

Armstrong Fluid Technology – https://armstrongfluidtechnology.com/

Armstrong Fluid Technology is a global provider of intelligent fluid flow and control solutions for heating, cooling, and plumbing systems. Their portfolio includes pumps, variable speed drives, packaged systems, and controls for commercial buildings, campuses, and industrial facilities. They help customers reduce energy use, improve comfort, and manage lifecycle costs while operating under increasing pressure to meet sustainability targets and report on performance.

Challenges

Armstrong needed a reliable way to connect smart pumps, variable speed drives, and building management interfaces back to cloud analytics and remote support tools, often from plant rooms and basements where fixed networking was unreliable or impractical. They had to ensure secure, managed access to site equipment without adding complexity for installers or facilities teams, and they needed a single connectivity platform that could scale across many projects, regions, and network conditions.

Results

By standardising on the Robustel R2010, Armstrong created a repeatable connectivity pattern for their smart HVAC solutions. Field devices can now send real-time performance data to central platforms, while engineers gain secure remote access for diagnostics and tuning. This has improved the stability and efficiency of connected systems, reduced time-to-diagnose issues, and laid a foundation for wider use of predictive maintenance across their installed base.

Connecting smart fluid systems to the cloud

Armstrong Fluid Technology has been pushing beyond traditional mechanical equipment towards fully connected, intelligent systems. Their pumps, controls, and optimisation platforms are designed to cut energy use and support more efficient buildings, but the value depends on a dependable link between field devices and cloud analytics. Many customer sites, however, present difficult networking conditions: plant rooms with limited cabling, brownfield buildings with mixed infrastructure, and projects where IT teams are cautious about opening up their internal networks.

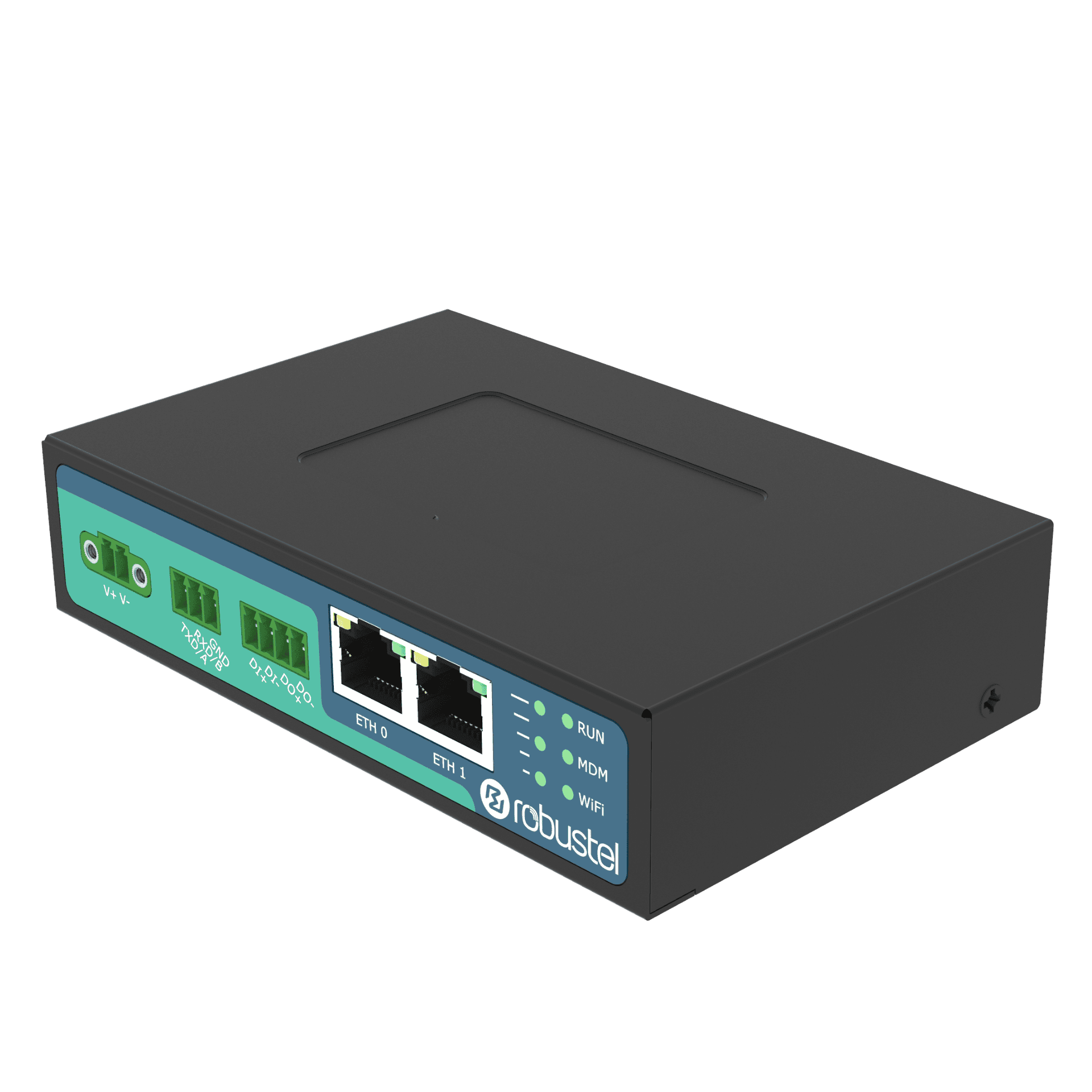

To keep projects moving, Armstrong needed an embedded connectivity solution that would work consistently across markets, tolerate harsh installation environments, and still meet the security expectations of modern building owners and IT departments. The Robustel R2010 became the core of that approach, giving each deployment a compact, industrial-grade cellular gateway that could sit close to the equipment and maintain a secure bridge to the cloud.

Business Challenges

1. Unreliable or unavailable site networking

Many HVAC and pump installations live in basements, rooftops, or plant rooms where access to the building’s IT network is limited or non-existent. Even when Ethernet is available, facilities and IT teams may be reluctant to route building services traffic over corporate infrastructure, or there may be no convenient run to the equipment location. This left Armstrong’s smart systems dependent on ad hoc solutions or customer-specific workarounds.

Commercially, that uncertainty adds risk to each project. Sales teams cannot assume that the customer’s network will support remote monitoring, and engineers must allow time for case-by-case integration. That slows down rollouts, increases commissioning effort, and can undermine the business case for energy-saving analytics when connectivity cannot be guaranteed.

2. Need for secure remote access without complexity

To deliver ongoing value, Armstrong engineers and partners need to see how systems behave in the field: pump curves, temperatures, pressures, and alarms across many sites. Without secure remote access, this often means more site visits for tuning, troubleshooting, and firmware changes. At the same time, building owners and IT teams need reassurance that any remote access path is controlled, encrypted, and auditable.

If connectivity and security are not handled cleanly, projects can stall at the approval stage. Stakeholders may worry about opening ports on firewalls, exposing building systems to the internet, or taking on long-term support risk. Armstrong needed a way to embed secure networking into their solution so that remote access felt like a designed feature, not an afterthought.

3. Scaling a repeatable connectivity pattern across markets

Armstrong delivers systems worldwide, often through partners and local contractors. Each region has its own mobile operators, regulatory environment, and installation practices. Relying on consumer-grade networking gear or bespoke designs for each project makes it hard to maintain consistent performance and support models. Documentation, training, and troubleshooting all become more complex when every cabinet looks different.

From a business perspective, this fragmentation limits scale. Armstrong wanted a standard connectivity building block they could reference in solution designs, train partners on, and support over the long term. That required hardware that could tolerate industrial conditions, support a broad range of cellular networks, and present a stable interface to their own control and analytics platforms.

Solution Overview

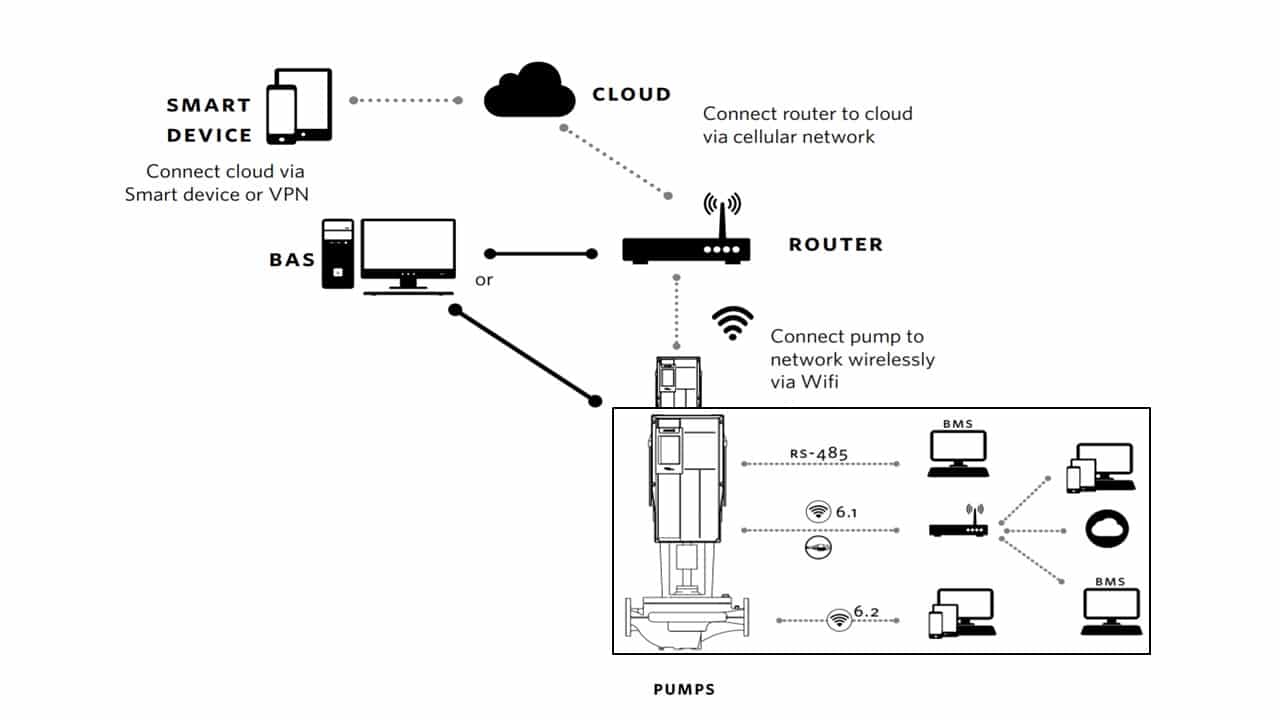

Armstrong selected the Robustel R2010 industrial cellular router as the embedded connectivity layer for their smart HVAC and pumping solutions. In a typical deployment, the R2010 is installed in the same panel as Armstrong controls or drives, with Ethernet links to local devices and a 4G LTE connection used to reach cloud-based monitoring and optimisation platforms. The router handles routing, firewalling, and secure tunnels, so field devices can focus on their control tasks while still streaming telemetry and receiving configuration updates.

From the operations side, the R2010 offers a consistent management interface for configuration and ongoing support. Installers can bring sites online by inserting a SIM card, applying a pre-agreed template, and validating connectivity through the built-in web interface or remote tools. Once deployed, the router maintains a stable connection where cabling would be difficult, and can switch between interfaces if required to preserve service. This creates a clear separation between building IT networks and the dedicated path used for Armstrong’s connected services.

Why Armstrong Fluid Technology chose the Robustel R2010

- Industrial-grade design: The R2010 is built for control panels and plant environments, with wide DC input range, DIN-rail mounting options, and robust EMC characteristics. This means it can be installed alongside drives and control hardware without compromising reliability.

- 4G LTE connectivity for difficult locations: Many pump rooms and HVAC spaces do not have easy access to corporate networks. The R2010 provides high-quality LTE backhaul, allowing Armstrong systems to connect from locations where running new cables or negotiating IT access would be slow or costly.

- Secure networking features: Support for VPN, firewall rules, and segmented traffic allows Armstrong to offer secure remote access that aligns with building IT policies. Sensitive control traffic stays isolated, while encrypted tunnels carry telemetry and management traffic back to cloud services.

- Flexible interfaces for system integration: With multiple Ethernet ports and support for standard IP protocols, the R2010 connects cleanly to pumps, drives, and controllers without demanding changes to existing control architectures. It becomes the bridge between local automation and remote analytics.

- Operational simplicity for partners and installers: A consistent configuration model and browser-based management make it easier for Armstrong’s teams and partners to deploy, commission, and support the connectivity layer. This helps reduce training overhead and avoids bespoke designs for each project.

Key Outcomes

By embedding a standardised industrial router into their offering, Armstrong turned connectivity from a project risk into a reliable part of their solution. Systems that once relied on local checks and occasional manual data collection can now be observed and tuned continuously, using the same patterns across many customer sites and geographies.

- Consistent connectivity across varied buildings: Smart pumps and HVAC equipment can now report performance data from basements, rooftops, and mechanical rooms without depending on each site’s IT network. This has made it easier to deliver connected services in both new and existing buildings.

- Improved remote diagnostics and support: Engineers can access live data and status information without always travelling to site, which shortens troubleshooting cycles and reduces disruption for building occupants.

- Better use of performance and energy data: Continuous telemetry from the field supports more accurate analysis of system efficiency, allowing optimisation and maintenance strategies to be driven by real operating conditions rather than periodic snapshots.

- Simpler, repeatable deployments: Projects now follow a common pattern for networking, which reduces design time, simplifies documentation, and makes it easier for regional partners and contractors to install and commission systems.

- Stronger customer confidence in connected systems: Building owners and facility managers see that connectivity and security have been considered as part of the system design, making conversations about remote access, data use, and long-term support more straightforward.

Featured Products

Robustel R2010 4G/LTE Router