Cutting energy waste in commercial buildings with the M1000:

How Robustel & Rubin Informatikai rolled out an energy-saving system across diverse commercial buildings.

Case Study – Fast Facts

Location

Hungary

Industry

Energy & Utilities

Product(s)

- M1000 (Note: Product now replaced by M1000-MP)

End Customer

Rubin Informatikai – https://www.rubin.hu/

Rubin Informatikai is a technology company that designs and operates energy-saving systems for commercial and public buildings. Their solutions connect meters, HVAC controllers, and local automation panels to central software that monitors consumption, identifies inefficiencies, and drives energy cost reduction. Projects range from individual buildings to multi-site portfolios, where reliability, scalable rollout, and predictable communication costs are critical.

Challenges

Rubin needed a way to connect energy meters and controllers in many buildings that lacked modern IP networks or standardised communication equipment. Existing installations used legacy serial interfaces and varied vendor hardware, while the energy-saving platform required consistent, dependable communication over 2G/3G across different locations and operators. They needed an industrial modem that could handle this diversity without complex on-site engineering.

Results

By embedding the M1000 in their solution, Rubin created a common communications layer for their meters and controllers, using 2G/3G networks where fixed connectivity was unavailable or uneconomical. The system delivered reliable data collection, reduced on-site work for each deployment, and enabled efficient scaling of their energy-saving service across a wide base of buildings.

Connecting legacy building systems to an energy-saving platform

Rubin Informatikai specialises in helping building owners reduce energy consumption by monitoring usage, adjusting control strategies, and highlighting waste. Their platform depends on timely, accurate data from electricity, heat, gas, and water meters, as well as from HVAC and other building control systems.

Many of the buildings they target were constructed long before IP networking became standard. Some have limited or no fixed-line connectivity in plant rooms, and field devices often expose only serial interfaces such as RS-232 or RS-485. To deliver their service at scale, Rubin needed a communications approach that would work across this mix of sites without requiring a bespoke design for every project.

Business Challenges

1. Heterogeneous legacy devices with serial-only interfaces

Many target buildings already had meters and controllers installed, often from different vendors and generations. These devices typically offered only RS-232 or RS-485 serial ports and were never designed to speak IP or work directly over cellular networks. Replacing them would have been expensive and disruptive, undermining the return on investment of the energy-saving project.

In day-to-day operations, this meant Rubin’s engineers needed a way to bring data from these serial devices into their central platform without placing a new IP-enabled controller on site. Any solution that required per-site redesign or additional hardware stacks would drive up engineering effort, increase installation time, and slow the rollout of new projects.

2. Limited or unreliable fixed-line connectivity in plant areas

In many commercial and public buildings, the plant room or meter location does not have easy access to the same local area network (LAN) used for office IT. Running new Ethernet cabling or provisioning dedicated fixed lines for each building would add cost and introduce delays. In some sites, building owners were reluctant to connect energy meters to their corporate network at all, citing security or organisational boundaries.

This created a practical challenge for Rubin. Without a simple, reliable way to backhaul data from the plant room to their central servers, they risked gaps in monitoring and the need for manual data collection. A wireless solution based on public mobile networks was attractive, but required equipment that could cope with varying signal quality and operator coverage while keeping communication costs predictable.

3. Need for repeatable, low-touch deployments across many sites

Rubin’s business model depends on deploying energy-saving systems across a large number of buildings, not just a handful of flagship sites. Each additional hour spent on configuration, cabling, or troubleshooting at a single location multiplies across the estate. They needed an approach that field technicians could learn once and apply many times, with minimal variation between projects.

From a commercial perspective, this meant avoiding complex, custom-built communication solutions and instead standardising on a single modem platform that could be configured and supported in the same way everywhere. A repeatable template would shorten project timelines, reduce the chance of deployment errors, and make it easier to support the estate over time.

Solution Overview

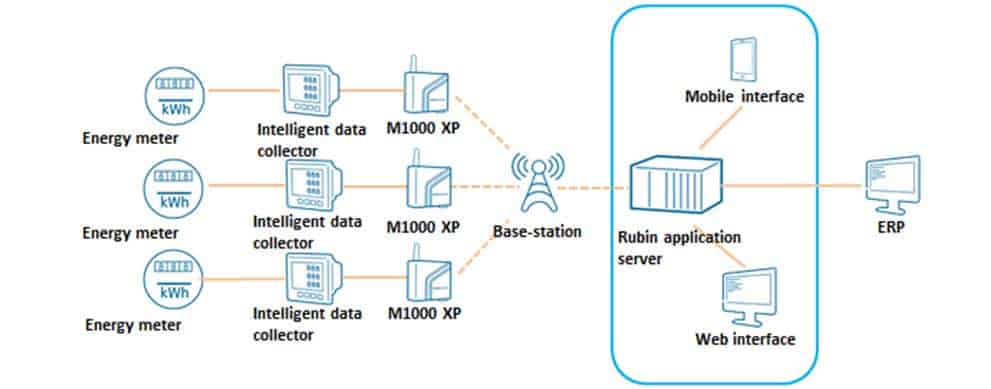

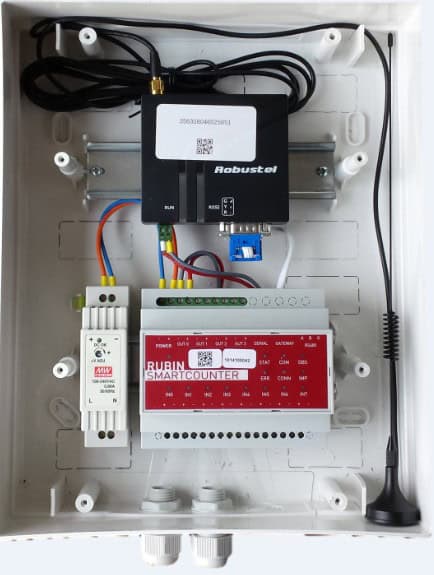

Rubin chose the M1000 industrial modem as the communication bridge between legacy field devices and their central energy-saving platform. The M1000 is installed in the plant room or meter cabinet, where it connects via RS-232 or RS-485 to existing meters and controllers. On the network side, it uses 2G/3G mobile connectivity to send measurement data and receive commands from Rubin’s data centre or cloud-hosted application.

In practice, technicians wire the M1000 to the serial output of each local controller or data concentrator, configure the dialing or packet data settings once, and then allow the modem to manage communication sessions with Rubin’s backend. The modem can be tuned to support the required communication pattern, whether periodic reporting, exception-based alarms, or scheduled data uploads. This arrangement gives Rubin a consistent, IP-reachable point in each building, even when there is no direct LAN access to the plant equipment.

Why Rubin chose the M1000

- Serial interface flexibility: The M1000 supports standard serial communication, allowing it to connect cleanly to existing meters and controllers without additional protocol converters. This simplifies cabinet design and reduces hardware counts.

- Industrial reliability in challenging locations: Plant rooms and energy cabinets can be dusty, noisy, and subject to electrical interference. The M1000’s industrial design is suited to these conditions, helping maintain stable communication links over the long term.

- Proven 2G/3G connectivity for dispersed sites: By using public mobile networks, Rubin can reach buildings where fixed-line upgrades would be slow or impractical. The M1000 provides dependable mobile connectivity that can be tuned to local operator conditions.

- Repeatable configuration model: Once Rubin defined a standard configuration for their application, field technicians could replicate it across many sites. This reduced training overhead and made support more predictable.

- Compact form factor for existing cabinets: The small size of the M1000 made it easy to integrate into existing meter panels and control cabinets without major redesign or additional enclosures.

Key Outcomes

From Rubin’s perspective, success meant being able to deploy their energy-saving system into many different buildings without being blocked by the condition of on-site communications. The M1000 helped turn that requirement into a practical, repeatable pattern.

“Robustel M1000 XP modem is a very easy to handle and integrate communication device. The on-board communication features shortened the integration time and time to market” – Dr. Tibor Takács – CTO of Rubin.

- Consistent data flow from diverse buildings: Energy consumption and operational data from meters and controllers now reaches Rubin’s platform reliably, enabling accurate analysis and optimisation.

- Lower deployment complexity per site: Using a single, standard modem with serial interfaces reduced the need for custom integration work at each building and shortened installation windows.

- Minimal disruption to existing infrastructure: Building owners could keep their current meters and control systems, avoiding costly replacement projects and associated downtime.

- Scalable service model: With a repeatable communications design, Rubin can expand their energy-saving offering to more customers and buildings without a proportional increase in engineering effort.

- Better visibility for optimisation and reporting: Regular, reliable data collection improves the quality of energy reports and makes it easier to demonstrate savings and justify further investment.

Featured Products

Robustel M1000-MP Modem