Understanding IoT Gateway Protocols: From Modbus and OPC UA to MQTT

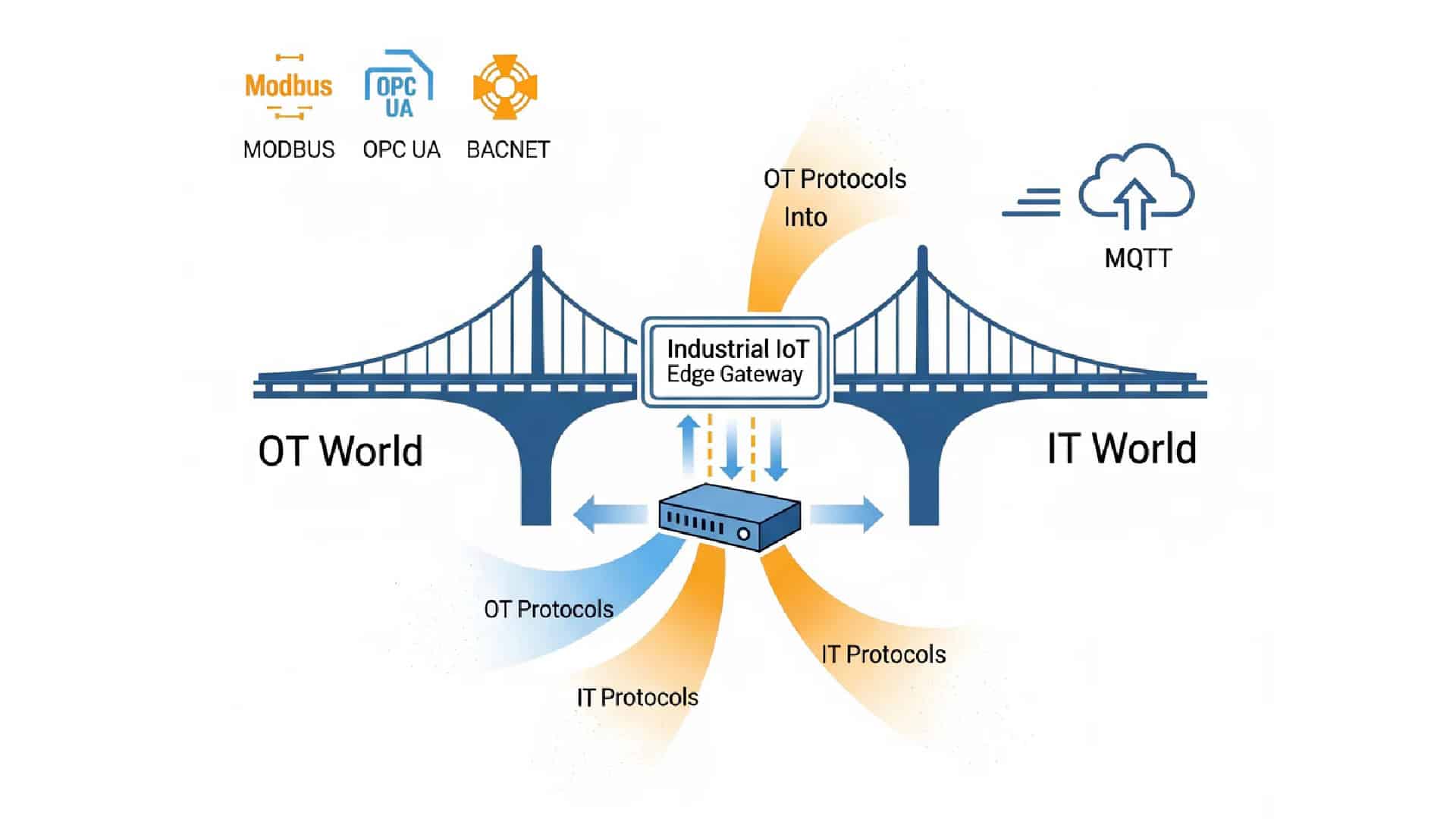

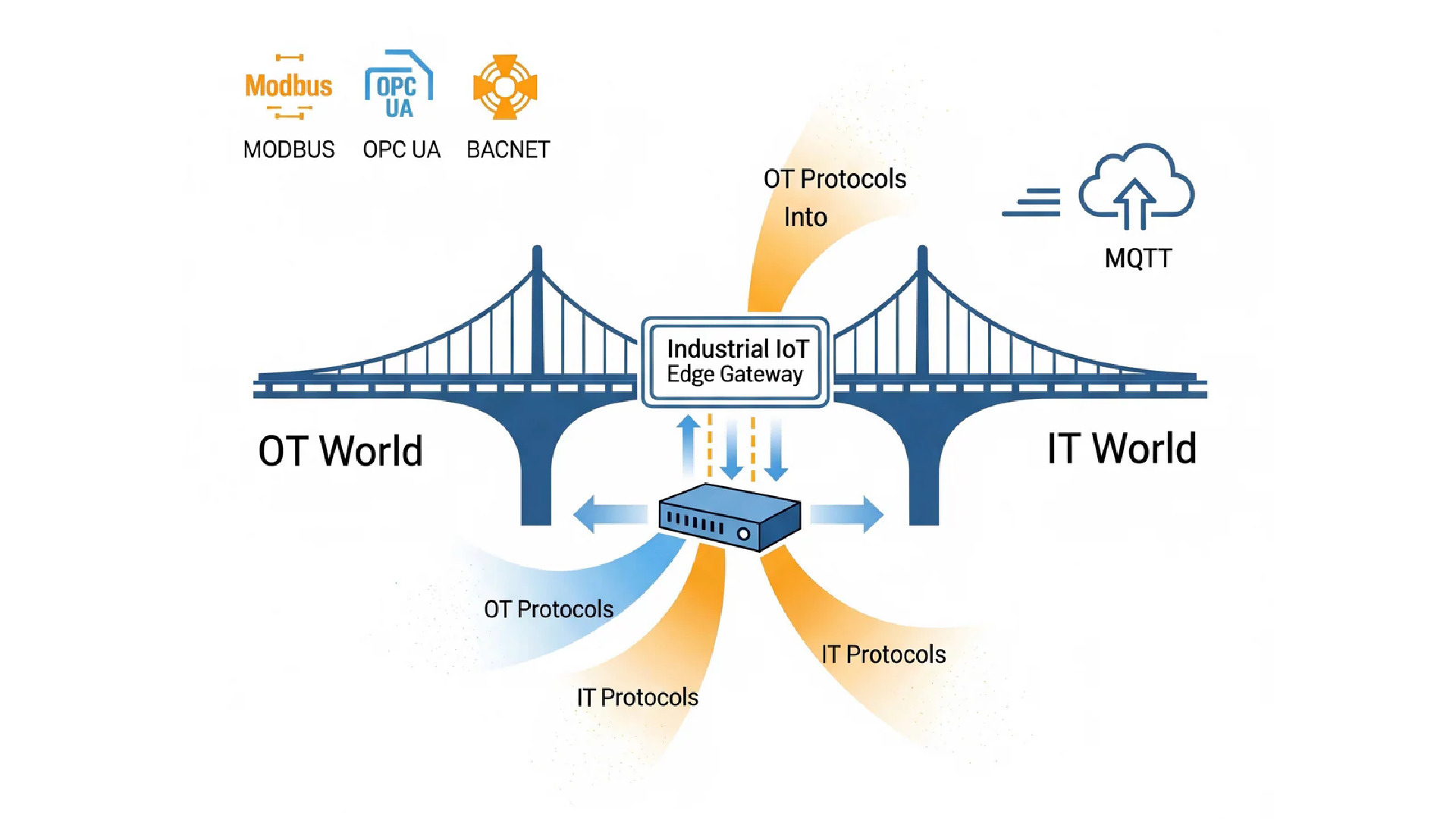

In the heat of a modern factory or smart building, a gateway’s most fundamental job is to act as a multilingual translator. On one side, it must handle the raw, legacy “chatter” of the factory floor—polling sensors via Modbus RTU or syncing with high-speed controllers over Modbus TCP. On the other side, it has to package that data for the cloud using the MQTT protocol, the global standard for lean, reliable IT communication.

This guide provides a clear roadmap to the most important protocols you’ll encounter in edge computing in IoT. We’ll demystify foundational OT standards like Modbus and OPC UA, explaining OPC UA is essential for securing modern industrial equipment.

We will also dive into the MQTT protocol, the de facto standard for modern cloud communication. By the end, you’ll see why EG5120, a truly powerful Edge Computing gateway isn’t just a bridge—it’s the intelligent engine that translates the payload and ensures your IT and OT systems finally speak the same language.

Ready to find the right “language” for your network? Let’s dive in!

Introduction of IoT Gateway Protocols: Bridging the Gap from Factory to Cloud

You have a factory floor full of high-value machinery and a powerful cloud platform ready to analyze the data. There’s just one problem: they don’t speak the same language. It is a common roadblock in the Industrial IoT. You might have an engineer with a PLC outputting critical data, but no easy way to get that information into an AWS or Azure dashboard.

This “language barrier” exists because of a fundamental split in network protocols. Your Operational Technology (OT) equipment—like PLCs and sensors—communicates using robust internet protocols designed for local reliability, such as Modbus or OPC UA. Meanwhile, your Information Technology (IT) systems and cloud platforms rely on MQTT, a lightweight standard built for global scalability.

To bridge this gap, your gateway must be a master “polyglot”. Understanding the most common IoT gateway protocols is the first step in choosing a device that can translate between these two worlds. By choosing the right framework, you can turn isolated machine data into a unified, cloud-ready stream.

OT Protocols: The Language of the Machine

For any industrial site, the “ground floor” of communication is built on network protocols designed for the rugged reality of the factory. These OT standards handle the raw data flow between sensors, PLCs, and controllers. Unlike standard internet protocols, they prioritize deterministic reliability over raw speed. To build a successful bridge to the cloud, a powerful industrial gateway must be fluent in these IoT gateway protocols.

What is Modbus: The Universal Workhorse

To understand the foundation of industrial networking, we have to start with the essentials: what is Modbus?

Developed in 1979, the Modbus protocol remains the undisputed king of the factory floor because it is open, simple, and remarkably reliable. It’s the universal handshake that allows a wide range of devices—from high-end PLCs to compact sensors like the Robustel S6000U—to share data without compatibility headaches.

When deploying an edge solution, you will primarily encounter two variants:

- Modbus RTU: This is the serial version of the protocol. It typically runs over RS-485 or RS-232 wiring and uses a compact binary format. It’s perfect for local, daisy-chained device networks where cost and simplicity are key.

- Modbus TCP: This takes the same core commands and encapsulates them into a TCP/IP packet. This allows the data to travel over modern Ethernet networks, making it easier to integrate with existing IT infrastructure.

Why Modbus protocol matters? For most projects, support for Modbus is non-negotiable. The real “aha!” moment for many engineers is realizing the power of a gateway that acts as a Modbus RTU to Modbus TCP bridge.

Imagine a scenario where you have a decade-old serial-based power meter at a remote site. By using an intelligent gateway, you can “translate” that older serial data into an Ethernet-friendly format. This allows your modern, high-speed monitoring systems to talk to legacy equipment seamlessly, extending the life of your hardware while bringing it into the digital age.

OPC UA: The Secure, High-IQ Standard for Industry 4.0

If Modbus is the universal handshake of the machine world, OPC UA (Open Platform Communications Unified Architecture) is the sophisticated, multilingual diplomat. While older network protocols were built just to move raw numbers, OPC UA was designed to move meaning.

What is OPC UA?

In the world of internet protocols, most systems just send a value (like “25.5”). Without context, you don’t know if that’s a temperature, a pressure, or an error code. OPC UA changes this by using a “rich data model”. It groups data into objects, so your IoT gateway protocols can see not just a number, but a “Pump” with a “Status”, “Manufacturer”, and “Install Date” all bundled together.

Why it matters?

As cyber threats move closer to the factory floor, “bolt-on” security is no longer enough. Unlike Modbus, which often lacks inherent protection, OPC UA has security built into its DNA.

- Built-in Defense: It uses industry-standard encryption and digital certificates to ensure that only authorized devices can “talk” to your machines.

- Platform Freedom: It is platform-independent. Whether your gateway runs on Linux, Windows, or an embedded RTOS, OPC UA works seamlessly across them all.

- Firewall Friendly: It simplifies IT/OT integration by using a single, secure port, making it much easier for IT teams to approve than legacy network protocols.

When evaluating an Industrial IoT Edge Gateway, support for OPC UA is no longer a “nice-to-have”. If your project involves complex machinery or requires high-level data integrity, OPC UA is the bridge that ensures your data arrives at the cloud with its context—and its security—fully intact.

IT Protocols: The Language of the Cloud

Once your gateway has gathered raw data from the factory floor, it must package that information for its journey across the internet. This requires network protocols designed for speed, low bandwidth, and unreliable connections. While OT protocols focus on the machine, IT protocols focus on the world beyond the local network.

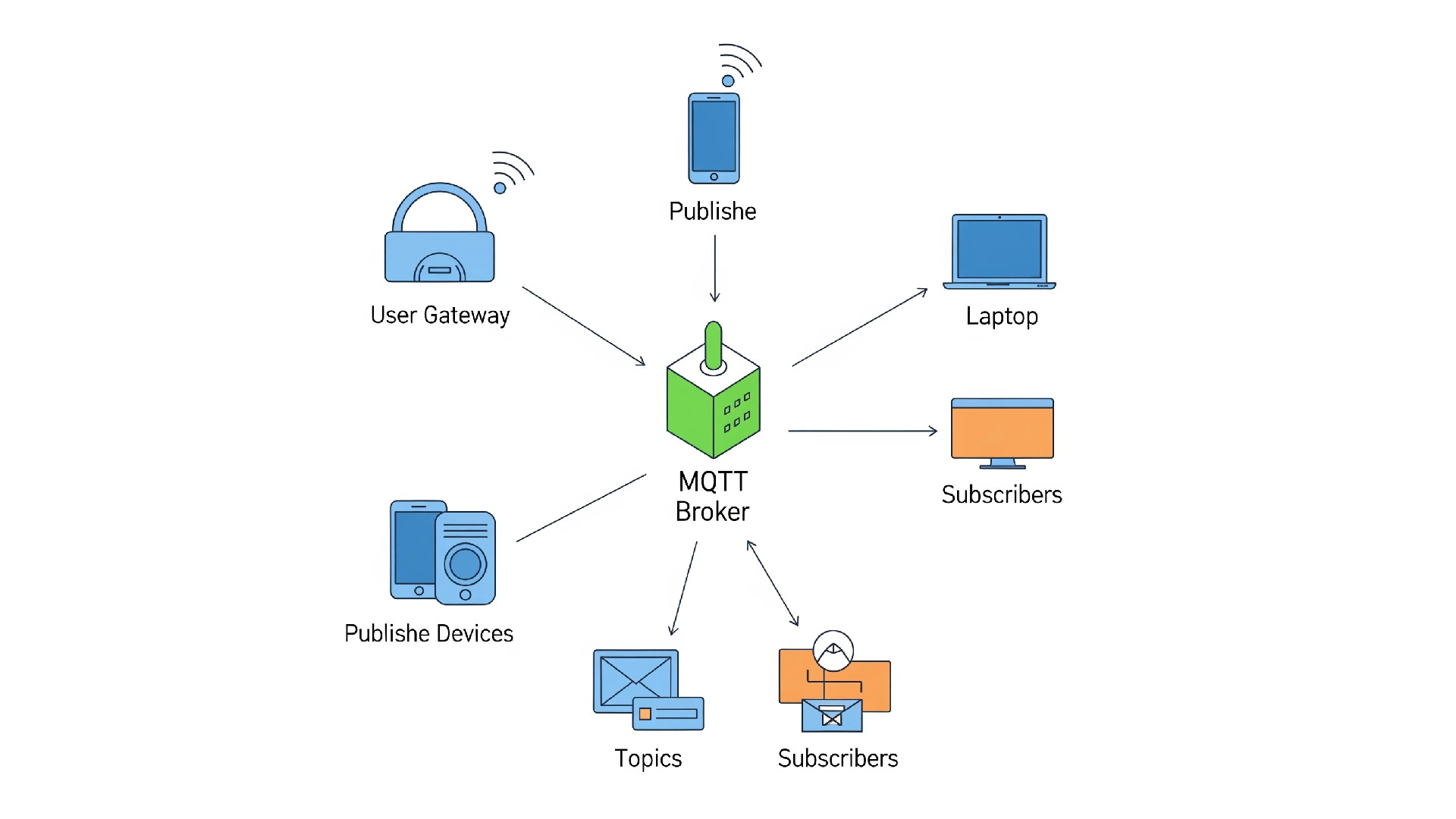

MQTT: The Modern Standard for IoT

If you are deploying an industrial project today, the MQTT protocol (Message Queuing Telemetry Transport) is almost certainly your primary choice. It has become the global standard for edge computing in iot because it solves the biggest headache of remote monitoring: limited or expensive bandwidth.

What is MQTT and how does it work?

This system decouples the data producer from the consumer. This means your cloud dashboard doesn’t need to know the IP address of your gateway, and your gateway doesn’t need to stay “awake” waiting for a request. This creates a highly scalable environment where adding new devices is a breeze.

Unlike traditional protocols that require a constant direct connection, MQTT uses a “publish-subscribe” model. Your gateways “publish” data to a central broker, and your cloud apps “subscribe” to the topics they need.

Why It Matters for Your Gateway?

In the world of internet protocols, efficiency is king. MQTT is incredibly lightweight, making it the perfect partner for gateways running on cellular networks where every kilobyte of data counts.

Because it is the “Northbound” standard, nearly every major cloud provider—including AWS IoT Core, Azure IoT Hub—supports it natively. When selecting an Industrial IoT edge gateway, ensuring it has robust MQTT support is the single most important step in future-proofing your IT architecture.

The Gateway’s Role: Protocol Conversion and Data Processing

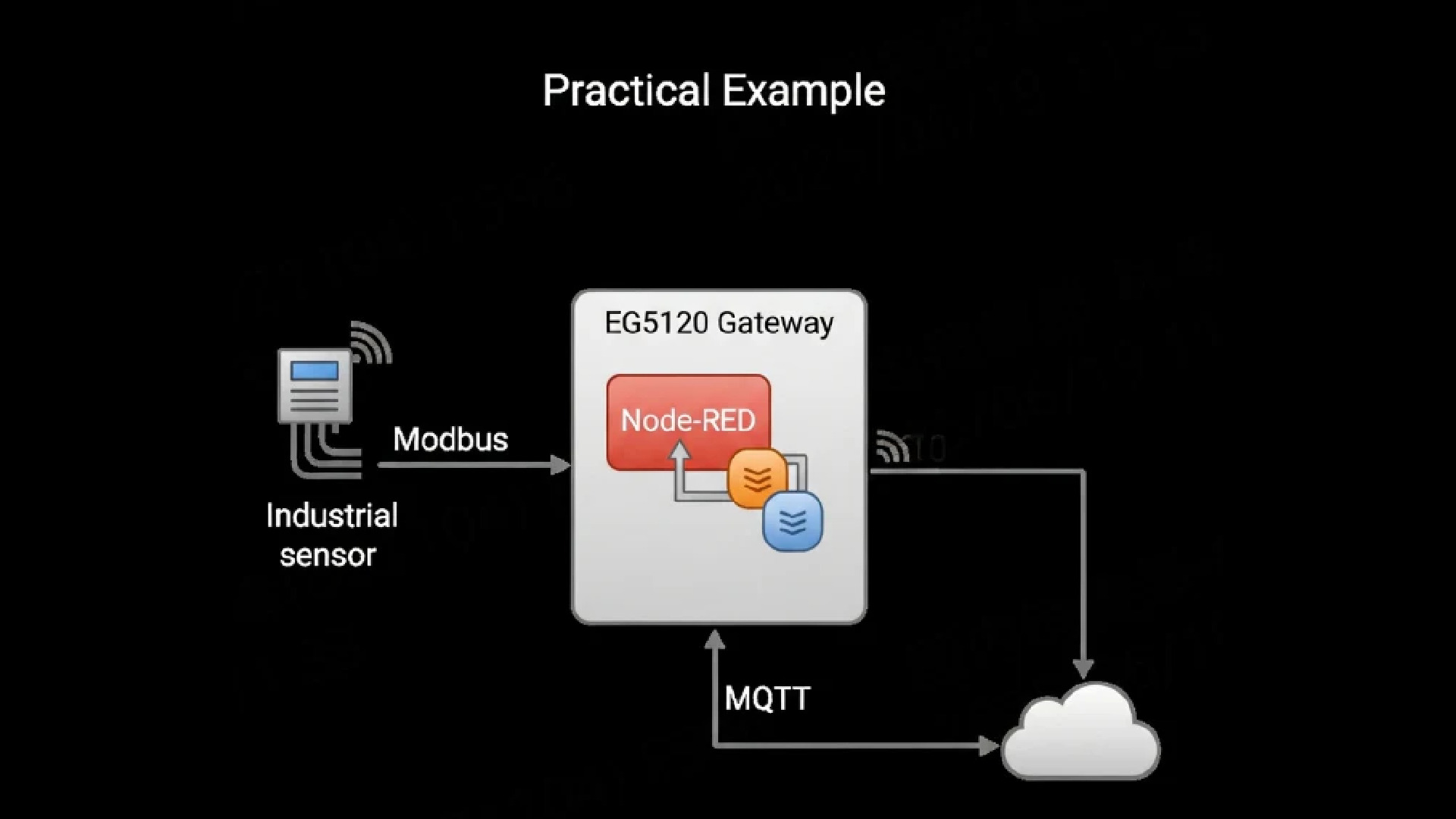

How does a device like the Robustel EG5120 manage the chaos of different IoT gateway protocols? It doesn’t just pass data through; it acts as an intelligent intermediary. By sitting between your machines and your network, it performs two critical roles that define the success of an IIoT deployment.

Watch: Discover the power of the EG5120 Edge Computing Gateway.

1. Seamless Protocol Conversion

The first task is acting as a “universal translator.” Using robust software—often enhanced by middleware like Robustel’s Edge2Cloud Pro—the gateway performs a Modbus poll or an OPC UA data pull from your field devices.

It then strips away the complex industrial formatting and converts the data into a standardized, web-friendly format like JSON. Finally, it publishes that clean data via the MQTT protocol to your cloud platform. This conversion ensures that your AWS or Azure dashboard receives organized information rather than a raw, unreadable stream.

2. Real-World Edge Computing

A high-performance industrial IoT edge gateway does more than translate; it “thinks” at the source. This is where you see the true edge computing benefits. Instead of sending every single data point to the cloud—which wastes bandwidth and increases storage costs—the gateway processes data locally.

Imagine a temperature sensor connected via Modbus RTU, where a Node-RED flow running on the EG5120 reads the Celsius value, converts it to Fahrenheit locally, and checks it against a specific threshold. Instead of flooding your network with constant updates, the system is designed for efficiency.

The result? The gateway only publishes an MQTT message if the temperature changes significantly or hits a critical alarm state, a “reporting by exception” strategy that saves massive amounts of data and slashes your cloud processing bills.

Conclusion: Unlocking Edge Computing Benefits through Protocol Mastery

Understanding iot gateway protocols is more than just a technical requirement; it is the foundation of a successful Industrial IoT strategy. As we’ve explored, this is a world of two distinct languages. On one side, you have the robust, time-tested network protocols of the OT world, like Modbus and OPC UA. On the other, you have the modern, scalable internet protocols of the IT world, specifically the MQTT protocol.

A true industrial IoT edge gateway, such as the Robustel EG5120, must be a master translator between these two realms. It isn’t enough to just move data; the gateway must provide the edge computing benefits of local processing, security, and protocol conversion to ensure your system remains efficient and secure.

By choosing a platform with broad protocol support and the intelligence to process data at the source, you can bridge the gap between your machinery and the cloud. The result is a seamless, future-proof data flow that turns raw machine chatter into actionable business intelligence.

Experience Protocol Mastery – Discover the Robustel EG5120 Edge Gateway.

FAQs

Q1: What is the difference between Modbus RTU and Modbus TCP?

A1: Modbus RTU is a serial communication protocol that runs over interfaces like RS485. Modbus TCP takes the same Modbus command structure and wraps it inside a TCP/IP packet for use over standard Ethernet networks. A good gateway can often bridge between the two.

Q2: Do I need to use MQTT to send data to the cloud?

A2: While you can also use protocols like HTTPS, MQTT is the dominant and highly recommended protocol for most IoT applications. Its lightweight, publish-subscribe model is far more efficient and scalable for device-to-cloud communication than traditional request-response protocols.

Q3: Can an IoT Gateway support multiple protocols at the same time?

A3: Yes. A powerful industrial IoT edge gateway like the EG5120 can simultaneously poll data from a Modbus RTU device on its serial port, an OPC UA server on its Ethernet port, and then publish all that data via MQTT to the cloud over its cellular connection. This multi-protocol capability is one of its key advantages.

About the Author

Robert Liao | Technical Support Engineer

Robert Liao is an IoT Technical Support Engineer at Robustel, specializing in industrial networking and edge connectivity. A certified Networking Engineer, Robert focuses on the deployment and troubleshooting of large-scale IIoT infrastructures. His work centers on architecting reliable, scalable system performance for complex industrial applications, bridging the gap between field hardware and cloud-side data management.