2026 Industrial IoT Edge Gateway Comparison: A Guide for OT & IT Professionals

Picking an Industrial IoT Edge Gateway is a high-stakes decision. In the rapidly evolving world of edge computing in IoT, the market is crowded with extremes. You might be tempted by the low cost of a DIY Raspberry Pi, the massive scale of a Dell server, or the rigid reliability of a Siemens or Rockwell controller. Each path offers a different promise, but choosing the wrong one can lead to expensive bottlenecks and field failures.

This guide cuts through the noise. We compare these industry heavyweights against the Robustel EG5120 using the six pillars that actually determine success in the field. Beyond just hardware, we explore the core edge computing benefits—like reduced latency and lower bandwidth costs—to see how these platforms handle real-world pressure.

Discover how the Robustel EG5120 bridges the gap. With an open Debian-based OS, integrated RCMS cloud, and rock-solid connectivity, it offers a versatile solution designed to handle the unpredictable realities of modern industry.

Introduction: The Critical Role of the Industrial IoT Edge Gateway

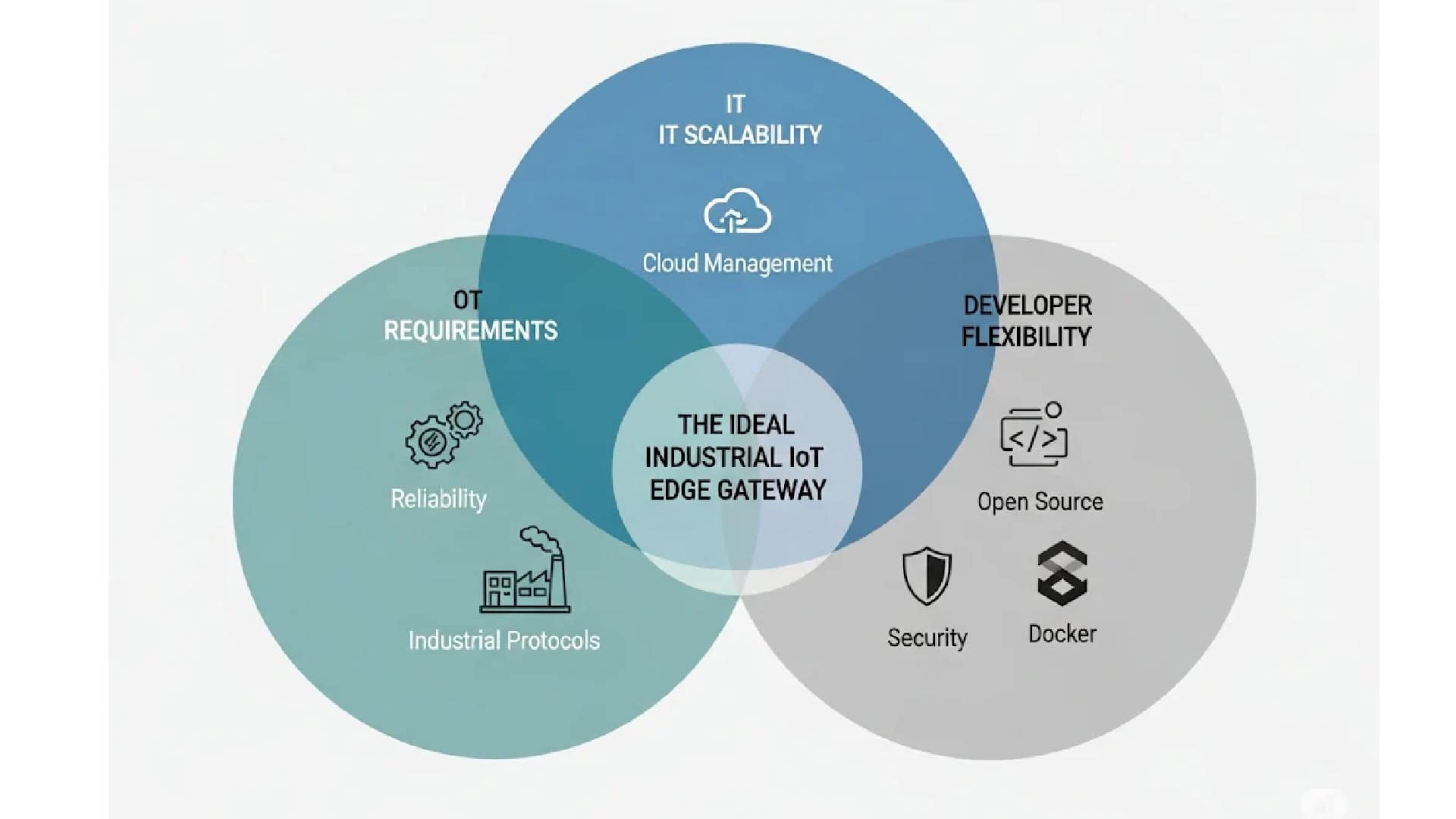

In a modern smart factory or remote job site, the Industrial IoT Edge Gateway acts as the central nervous system. It is the essential bridge between the physical world of Operational Technology (OT)—the sensors and machinery—and the digital world of Information Technology (IT).

However, a gateway does much more than just move data. In the world of edge computing in iot, these devices must be intelligent and secure enough to process data locally. This is where the true edge computing benefits come into play: by handling data at the source, you reduce latency, save on bandwidth, and ensure your operations stay online even if the cloud connection flickers.

But here is the challenge: the market is flooded with options. Choosing the wrong hardware can stall a project before it even starts. To help you navigate this, we’ve put together a comprehensive Industrial IoT Edge Gateway Comparison. We will look at how the industry’s big players—including Raspberry Pi, Siemens Simatic IoT2050, Rockwell Optix Edge, and Dell—stack up against the Robustel EG5120.

Making the right choice isn’t just about specs; it’s about the long-term success of your entire project. Let’s dive into the details.

How to Choose An Industrial IoT Edge Gateway: The 6 Pillars That Actually Matter

A fair comparison of industrial IoT Edge gateway goes beyond the surface-level spec sheet. It requires a framework built on how these devices actually perform when things get tough. To avoid the common traps of an Industry 4.0 deployment, these six dimensions are the essential benchmarks:

1. Hardware Performance & Industrial Readiness

The hardware must be powerful enough for edge computing tasks and rugged enough for the target environment. This includes CPU performance, memory, and, crucially, environmental specifications like operating temperature and physical protection. Robust hardware is non-negotiable .

2. Cellular Connectivity & Network Resilience

For deployments in remote locations or as a primary/backup connection, built-in cellular (4G/5G) capabilities are essential. Key features to consider include global band support, dual-SIM failover for resilience, and support for modern cellular standards.

3. Operating System & Software Flexibility

The OS is the foundation for your application. Key questions include: Is it open (like Linux) or proprietary? Does it support modern development tools like Docker containers? How easily can developers integrate OT protocols and build custom applications on their Edge Gateway?

4. Security & System Reliability

Security is paramount in OT/IT convergence. An Industrial IoT Edge Gateway must have a hardened OS, a robust firewall, comprehensive VPN support, and secure boot capabilities. Reliability features like automatic system failback are also critical for unattended devices.

5. Scalability & Remote Management

A single IoT Edge Gateway is easy to manage; a fleet of thousands is not. A truly scalable solution must be accompanied by a powerful, centralized cloud management platform for monitoring, configuration, OTA updates, and secure remote access.

6. Total Cost of Ownership (TCO)

TCO goes far beyond the initial hardware price. It encompasses the costs of software development and integration (especially for OT protocols), certifications, deployment, ongoing management, and potential downtime for your IoT Gateway fleet.

The Contenders: Unlocking Edge Computing Benefits in 2026

To understand the real-world edge computing benefits for your project, we have to look past the marketing and see how these devices handle actual field stress. While every manufacturer has their own naming conventions, each of these “contenders” is designed to sit at the edge of your network, turning raw data into actionable insights.

Raspberry Pi 4 Model B: The DIY Prototyper

- Cellular: Not built-in; requires third-party USB dongles or HATs, which adds complexity and potential points of failure.

- Overview: The DIY baseline, often used as a makeshift IoT Gateway for prototyping.

- Strengths: Extremely low initial cost, highly flexible open-source OS, massive community.

- Weaknesses: Not industrial-grade (consumer components, limited temp range, SD card reliability), lacks integrated and certified cellular connectivity, no integrated fleet management, requires extensive manual effort for security and certifications.

- Best For: Proof of Concept (PoC) and hobbyist projects.

Siemens Simatic IoT2050: The OT Standard

- Cellular: Available via optional Mini PCIe cards.

- Overview: An IoT Gateway from an OT automation leader, designed for Siemens ecosystems.

- Strengths: High industrial reliability, excellent support for Siemens PLCs and protocols, robust hardware.

- Weaknesses: Its Yocto-based OS can have a steeper learning curve than Debian. Cellular connectivity is an add-on, not always standard.

- Best For: Existing Siemens factory environments where Ethernet is already available.

Rockwell Automation Optix Edge Gateway: The Ecosystem Specialist

- Cellular: Not a primary feature; typically relies on existing plant-wide network infrastructure (Ethernet/Wi-Fi).

- Overview: An Edge Gateway from another OT powerhouse, for deep integration with Rockwell’s FactoryTalk ecosystem.

- Strengths: Premier integration with Logix controllers and FactoryTalk software. Excellent for factory floor data aggregation.

- Weaknesses: Lacks integrated cellular options, making it unsuitable for remote or mobile applications without additional hardware. It is a specialized tool for a specific ecosystem.

- Best For: Deep factory-floor data aggregation within the Rockwell ecosystem.

Dell Edge Gateway 5000 Series: The IT Powerhouse

- Cellular: Optional, via modular expansion slots for various 4G/5G modems.

- Overview: A rugged Edge Gateway from an IT hardware giant.

- Strengths: Powerful Intel processors, excellent build quality, and global support from Dell.

- Weaknesses: More focused on IT edge applications than deep OT protocol integration out-of-the-box. It may require significant investment in third-party software and integration effort to add OT capabilities.

- Best For: Deep factory-floor data aggregation within the Rockwell ecosystem.

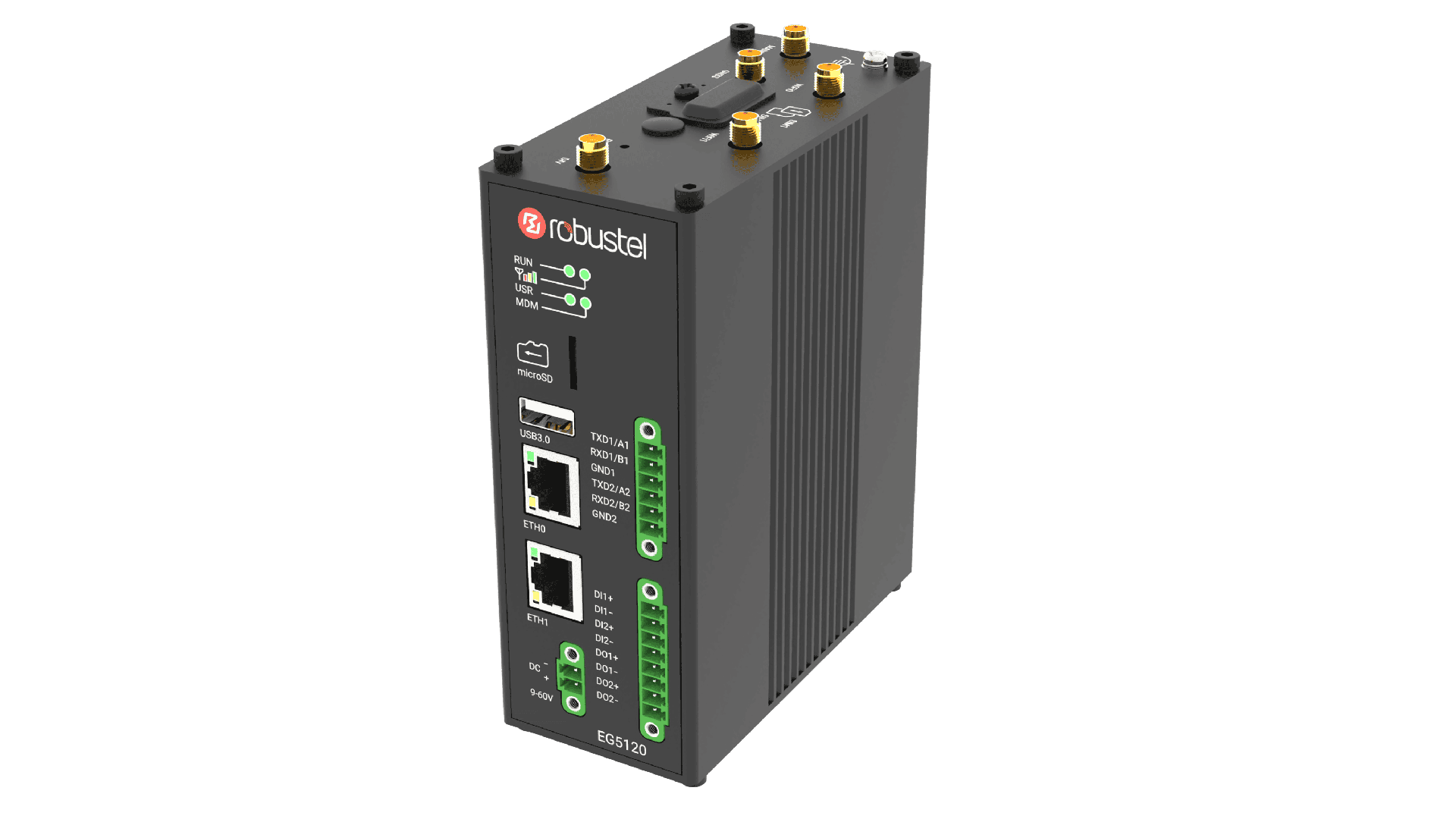

Robustel EG5120 The Versatile All-Rounder

- Cellular: Built-in Global 4G LTE Cat 4 with Dual SIM failover .

- Overview: A modern industrial IoT edge gateway designed to balance openness, performance, and industrial-grade features.

- Strengths: Powered by a high-performance ARM processor, it runs Debian-based RobustOS Pro, offering a familiar Linux environment. It features fully integrated and globally certified cellular connectivity, extensive industrial interfaces, and seamless integration with the powerful RCMS cloud platform. This makes it a strong Industrial IoT Edge Gateway Comparison candidate.

- Best For: Professional-scale deployments that need reliable cellular, cloud management, and software flexibility.

| Selected EG5120 Specifications: | |

| Feature Category | Specification |

| System | |

CPU | Quad-Core ARM Cortex-A53, 1.6 GHz (NXP i.MX8) |

| RAM / Storage | 2 GB DDR4 / 16 GB eMMC |

| Connectivity | |

| Cellular | Global 4G LTE Cat 4 (Dual SIM Failover) |

| Ethernet | 2 x Gigabit Ethernet (10/100/1000 Mbps) |

| Industrial Interfaces | 2 x RS232/RS485, 2 x DI, 2 x DO |

| Software | |

| Operating System | RobustOS Pro (Debian 11 based with LTS) |

| Containerization | Docker support |

| IoT Stack Support | Node-RED, MQTT, InfluxDB, Grafana |

| Industrial Protocols | Modbus, OPC UA, BACnet, DNP3, and more |

Robustel EG5120

Comparative Analysis Table

| Features | Raspberry Pi 4 | Siemens IoT2050 | Rockwell Optix Edge | Dell Edge Gateway 5000 | Robustel EG5120 |

Device Type | Single-Board Compute | IoT Gateway | Edge Gateway | Edge Gateway | Industrial IoT Edge Gateway |

| Processor | ARM Cortex-A72 | TI ARM (Sitara) | Intel Atom | Intel Atom/ Core | ARM Cortex-A53 (NXP i.MX8) |

| Integrated Cellular | No (Requires Add-on) | No (Requires Add-on) | No | Optional Add-on | Yes (Global 4G, Dual SIM) |

| Operating System | Raspberry Pi OS (Debian) | Simatic OS (Yocto) | Proprietary | Various (Ubuntu, etc.) | RobustOS Pro (Debian 11 LTS) |

| Docker Support | Manual Install | Yes (Advanced) | Limited/No | Yes | Yes (Manual Install via App) |

| Cloud Management | DIY / 3rd Party | MindSphere | FactoryTalk | Dell / 3rd Party | RCMS (Fully Integrated) |

| Security Certification | No | Industrial Standards | Industrial Standards | IT Standards | IEC 62443-4-1, Pen Tested |

Edge Computing in IoT: Why the Robustel EG5120 Wins on the Factory Floor

While every contender in this Industrial IoT Edge Gateway comparison has a specific niche, the real test is how a device handles the “messy” reality of an industrial rollout. Most platforms force you to choose between the flexibility of a DIY setup and the rigid security of a legacy brand.

The Robustel EG5120 is designed to bridge that gap. By combining the openness of a PC with the ruggedness of an industrial controller, it unlocks the full spectrum of edge computing benefits—giving you a platform that is as easy to program as it is to deploy in the middle of nowhere.

Robust, Integrated Cellular Connectivity

Unlike many alternatives that treat cellular as an optional, complex add-on, the EG5120 integrates Global 4G LTE with Dual SIM failover as a core feature. This provides crucial network resilience right out of the box, making it ideal for remote deployments or as a reliable backup to wired connections. The hardware is fully certified with major carriers like AT&T and Verizon, eliminating a major hurdle for commercial deployments.

Open OS and Cost-Effective OT Integration

The Debian-based RobustOS Pro on the EG5120 offers unparalleled flexibility. Furthermore, Robustel provides its Edge2Cloud Pro middleware, which supports common industrial, building, and power protocols (like Modbus, OPC UA, BACnet, etc.) out-of-the-box. This powerful middleware for this IoT Gateway significantly reduces software development costs and complexity .

Simplified Fleet Management with RCMS

This is a critical advantage. Robustel’s RCMS is built for ease of use and scalability, offering features like Zero-Touch Provisioning. RCMS provides a unified, secure, and cost-effective solution for monitoring, updating (including containers), and remote access right out of the box, significantly lowering the TCO.

A Modern Approach to Industrial Security

Robustel’s commitment to security is proven. The development lifecycle for RobustOS Pro is IEC 62443-4-1 certified , and the OS undergoes regular third-party penetration testing. This provides a verifiable, standards-based level of security that is crucial for any serious Industrial IoT Edge Gateway Comparison.

Conclusion: Unlocking Edge Computing Benefits with the Right Gateway

This Industrial IoT Edge Gateway comparison makes one thing clear: there is no “magic bullet” for every project. The right choice always depends on your specific environment and your team’s expertise.

However, if you are looking to capture the full range of edge computing benefits—without the fragility of a DIY board or the high cost of legacy “vendor lock-in”—the Robustel EG5120 stands out as the modern standard.

By blending the open-source freedom of the Raspberry Pi ecosystem with the rugged reliability and integrated cellular resilience required for the field, the EG5120 offers a future-proof path for edge computing in iot. It’s a solution that scales as fast as your business, backed by the security and cloud management tools needed to keep a global fleet running smoothly.

Stop compromising on your edge infrastructure.

Why choose between the flexibility of open-source and the reliability of industrial hardware? Get the best of both worlds with a gateway designed to bridge the gap between the factory floor and the cloud. Explore the Robustel EG5120 Today!

FAQs

Q1: What’s the difference between an “Edge Gateway” and an “IoT Gateway”?

A1: The terms are often used interchangeably. Generally, an ” IoT Gateway ” is any device that connects IoT devices to the cloud. An ” Edge Gateway ” specifically implies that the device has significant onboard processing power to perform “edge computing” tasks (like local data analysis, filtering, and running applications) before sending data to the cloud. The Robustel EG5120 is both.

Q2: Is it difficult to migrate my Docker application from a Raspberry Pi to the EG5120?

A2: No, it’s generally very straightforward. Since both use ARM architecture and the EG5120’s Debian-based RobustOS Pro fully supports Docker (as a user-installable app), you can often run the same container image with minimal changes. The main work involves adapting your app to use the EG5120’s industrial interfaces.

Q3: How does the security of the EG5120 Industrial IoT Edge Gateway compare to others?

A3: The EG5120’s security is very strong and transparent. It is developed under the IEC 62443-4-1 international standard for industrial cybersecurity and is independently penetration tested. This provides a verifiable, standards-based level of security that is competitive with and, in terms of open validation, sometimes clearer than that of proprietary systems.

About the Author

Yang Tao | Founder & CEO

Robustel Yang Tao founded Robustel in 2010 with a vision to simplify industrial connectivity. Today, he leads a global team of over 300 experts, shipping mission-critical IoT solutions to more than 100 countries.

A firm believer in technical excellence, Yang dedicates 15% of revenue to R&D and operates a proprietary 5G smart factory. His commitment to security is backed by world-class certifications (IEC 62443, ISO 27001), ensuring that Robustel’s hardware is as secure as it is innovative.