Stabilising Power Distribution in Brazil:

How Robustel & CPFL Energia used the R1520 to improve protection and control across its urban distribution network.

Case Study – Fast Facts

Location

Brazil

Industry

Energy & Utilities

Product(s)

- R1520

- RCMS

End Customer

CPFL Energia – https://www.cpfl.com.br/

one of Brazil’s largest private electricity groups, responsible for power generation, transmission, and distribution across multiple states. The company serves millions of residential, commercial, and industrial customers in both urban and rural areas. Its networks include a mix of substations, reclosers, and automation assets that must operate reliably in demanding environments. As a regulated utility, CPFL is under constant pressure to improve service continuity, safety, and efficiency while managing costs.

Challenges

CPFL needed secure 4G/LTE connectivity and VPN services for reclosers and automation devices installed in urban distribution cabinets. The existing approach relied on separate routers and time servers, which increased hardware count, wiring complexity, and points of failure at each site. At the same time, operations teams lacked clear, centralised visibility into field communications and device health across a large and growing distribution footprint.

Results

By standardising on the R1520 and RCMS, CPFL consolidated routing, VPN, and time synchronisation into a single device per cabinet, simplifying the physical design and reducing installation effort. Communications for protection and control systems became more consistent and reliable, while RCMS introduced central monitoring and configuration, helping to lower support overhead and create a repeatable pattern for future deployments.

Modernising protection and control in a dense urban grid

CPFL Energia operates one of Brazil’s largest electricity distribution networks, serving millions of residential, commercial, and industrial customers. Its medium-voltage assets in cities such as reclosers and automated switches must communicate reliably with control centres to support protection schemes, fault isolation, and fast restoration.

As the utility expanded and upgraded its automation systems, it needed a repeatable way to connect field devices over cellular networks while keeping equipment count, cabinet space, and operational complexity under control. The communications design had to be robust enough for critical infrastructure, simple enough to deploy at scale, and transparent enough for operations teams to support over the long term.

Business Challenges

1. Keeping critical protection assets online and in sync

Reclosers and automated switches sit at key points in the medium-voltage network, where any failure in protection or control can quickly translate into visible outages for homes, businesses, and public services. These devices rely on dependable communications to send telemetry, receive commands, and participate in coordinated protection schemes. If the communications link drops or becomes unstable, operators lose real-time insight and may have to rely on slower manual processes during fault conditions.

Alongside connectivity, time synchronisation is fundamental. Event logs, fault records, and protection actions must share a consistent time reference so engineers can reconstruct incidents accurately and verify that protection schemes are behaving as intended. Using separate time servers added another dependency in the chain. Any drift, misconfiguration, or failure at this layer risked undermining the value of high-quality field data, making it harder to diagnose issues and prove performance to regulators or internal stakeholders.

2. Managing cabinet complexity and field support at scale

Most urban distribution cabinets already contain a mix of protection relays, control hardware, power supplies, and wiring. The earlier architecture, which combined a dedicated cellular VPN router with a stand-alone time server, increased hardware count, cabling, and power consumption in every cabinet. More devices meant more mounting hardware, more sources of heat, and more potential points of failure in confined spaces. Each additional box also had its own configuration and lifecycle to manage, adding friction for both installation and maintenance teams.

From an operational standpoint, this complexity translated directly into higher cost to serve. Field engineers had to be familiar with multiple devices at each site, and a fault in either communications or timing equipment could trigger site visits, even when the underlying protection equipment was functioning correctly. Over a wide network of cabinets, these incremental inefficiencies accumulate—driving up truck rolls, extending fault investigation times, and complicating planned upgrade programmes.

3. Gaining fleet-level visibility and a repeatable design pattern

CPFL’s distribution footprint spans many regions and a large number of sites, each with its own environmental conditions and access constraints. Without centralised visibility into the health and configuration of communications equipment, operations teams often had to rely on indirect signals—such as alarms from SCADA or reports from local staff—to infer where problems might be. This made proactive maintenance difficult and slowed down response when issues arose, especially if communications faults were intermittent.

At the same time, the utility needed a design that could scale beyond initial projects. Ad-hoc cabinet builds and one-off configurations might work for pilots, but they create long-term headaches when dozens or hundreds of sites must be supported over many years. CPFL was looking for a standardised communications building block it could deploy repeatedly: a combination of hardware and management tools that would be consistent enough for engineering teams to trust, transparent enough for operations to manage, and flexible enough to support future upgrades in its distribution automation roadmap.

Solution Overview

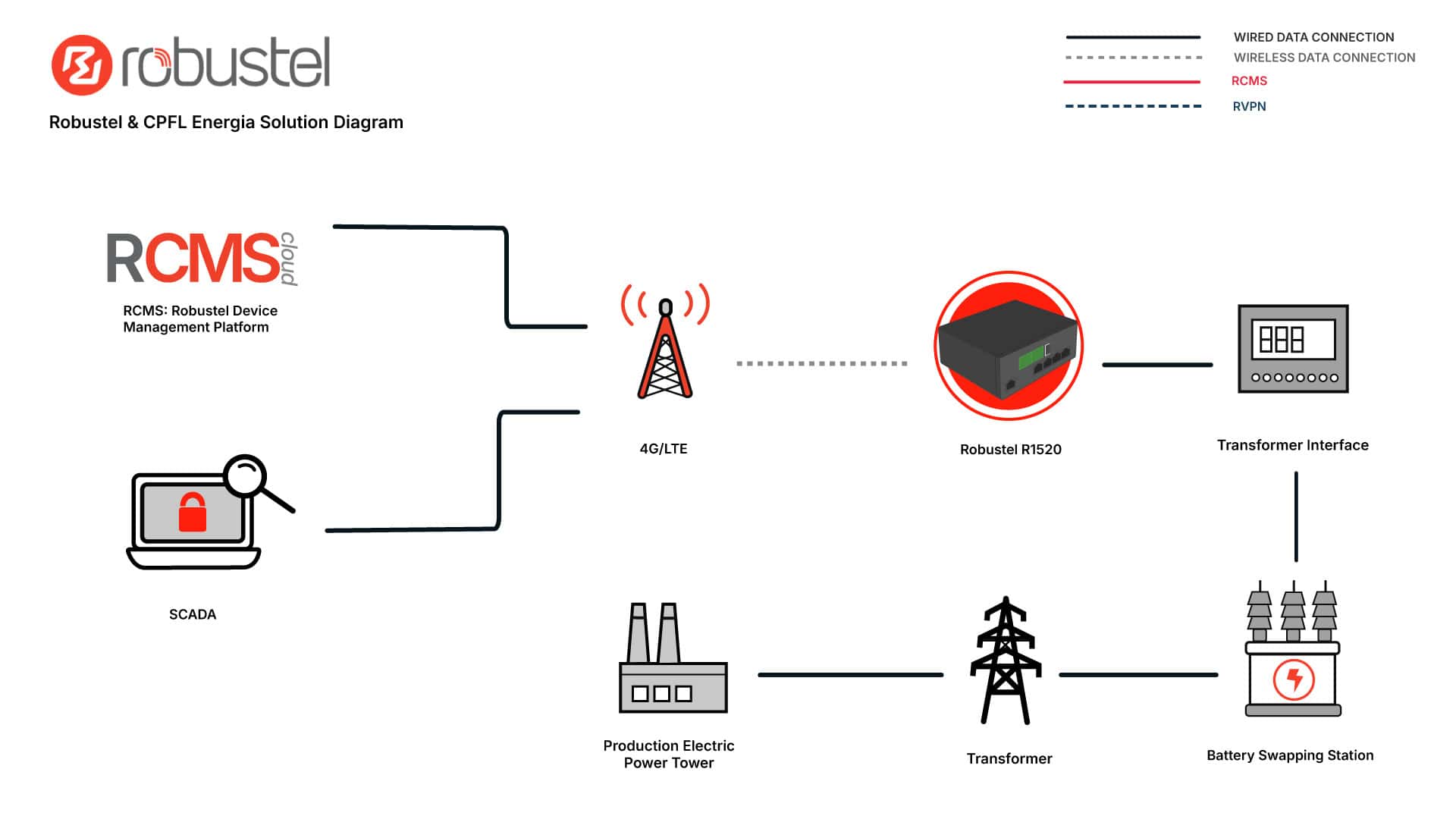

CPFL Energia chose to simplify its cabinet design by using the Robustel R1520 as the central communications node at each location. The router provides secure 4G/LTE backhaul, VPN termination, and time synchronisation functions in a single device, connecting field automation equipment to control systems over public cellular networks. Fleet-wide monitoring and configuration are handled through RCMS, giving engineers a single pane of glass for deployed routers.

In practice, the R1520 is mounted inside the protection or recloser cabinet and connects to local devices over Ethernet. It establishes encrypted tunnels back to the utility’s core network, providing a secure path for SCADA data and remote control. Using its positioning and time features together with SNTP, it can supply a consistent time source to connected equipment, helping align event logs and protection actions. Through RCMS, engineers can see which routers are online, review configurations, and push firmware or settings changes without travelling to site.

Why CPFL Energia chose the R1520:

- Integrated feature set: The R1520 could act as both cellular VPN router and time synchronisation source, removing the need for a separate NTP device and reducing the number of boxes in each cabinet.

- Industrial design for utility environments: Its rugged enclosure, extended temperature range, and flexible power input made it suitable for installation in distribution cabinets exposed to heat, vibration, and electrical noise.

- Secure cellular connectivity: Built-in VPN support and firewalling enabled CPFL to move critical communications over public 4G/LTE networks while maintaining a private, controlled path back to central systems.

- Centralised fleet management with RCMS: RCMS provided the visibility and remote management capabilities needed to operate a large installed base of routers, including status views, configuration, and firmware management from one platform.

- Scalability for ongoing projects: The R1520 and RCMS combination gave CPFL a repeatable building block that could be used across new and existing sites, supporting long-term grid modernisation plans.

Key Outcomes

From CPFL Energia’s perspective, success meant more than simply installing new hardware. It required a communications pattern that was reliable in operation, manageable at scale, and justifiable in terms of cost and complexity.

- A repeatable pattern for future deployments: The utility now has a proven design it can apply across additional substations and automation projects, reducing engineering effort for each new rollout.

- Simplified cabinet architecture: One device now provides routing, VPN, and time synchronisation functions, reducing wiring, power feeds, and mounting hardware in each recloser or automation cabinet.

- More reliable communications for protection and control: Secure 4G/LTE links and consistent time synchronisation support dependable operation of protection schemes and faster analysis of fault events.

- Improved operational visibility: Central monitoring through RCMS helps teams see which sites are online, which may need attention, and which configurations are in use, without waiting for incident reports.

- Lower lifecycle cost per site: Fewer devices and better remote management reduce both the upfront cost of deployments and the ongoing effort required to maintain communications equipment in the field.

Featured Products

Robustel R1520 4G/LTE Router

RCMS – Cloud Device Management