Solar PV Monitoring for Rooftops, Warehouses, and Remote Depots

A Robustel Application Example

Application Example – Fast Facts

Industry

Energy & Utilities, commercial and industrial solar PV portfolios, warehouses, logistics depots, municipal rooftops

Product(s)

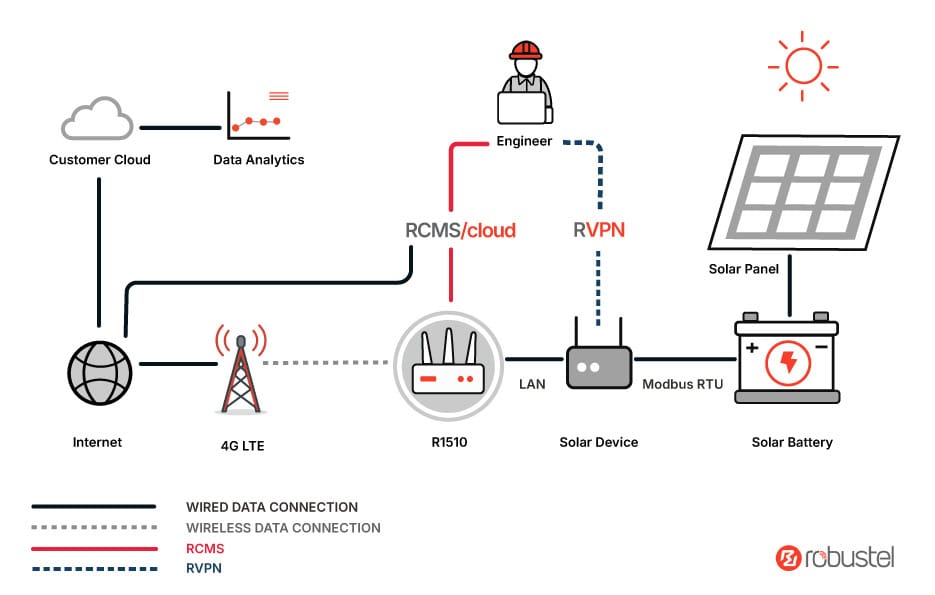

Robustel R1510 Router; RCMS (RobustLink, RobustVPN)

Challenges

Solar arrays on rooftops, warehouses, and remote depots need live production and fault visibility for performance guarantees and compliance reporting. Many of these sites don’t have dedicated fibre, and the building owner doesn’t want third-party equipment on their LAN.

Expected Outcomes

Install one R1510 per site to give inverters, meters, or local PV controllers a secure cellular backhaul. Central teams get output, alarms, and availability in RCMS without waiting on landlord IT or sending technicians to investigate every dip in generation.

Solar PV Monitoring Simplified

Most commercial solar portfolios are not one big solar farm. They’re 80 rooftops across different landlords, a few logistics yards, and a handful of municipal or utility buildings. Every array has financial expectations tied to it often under a power purchase agreement (PPA) or internal sustainability target — but not every site has proper connectivity, clean IT ownership, or someone on-site who even knows where the inverter room is.

Operations teams are held accountable for daily production and fault response. But they often find out about issues late, through billing exceptions or angry calls, not through telemetry. Why? Because the inverter or meter is offline, the site LAN is locked down, or there’s simply no broadband connection in that depot.

The Robustel R1510 solves that problem by giving each solar site its own managed cellular uplink. The inverter, energy meter, or PV controller connects to the R1510 locally; the R1510 reports status upstream over LTE; and RCMS gives the operator a live view of the entire portfolio. No dependence on customer IT. No blind spots. No waiting for next month’s data to discover last week’s failure.

Business Challenges

Before we talk architecture, let’s talk what actually hurts: missed output, slow response, and no proof. These are the pressures asset owners, O&M providers, and energy service companies live with every day.

- You can’t always touch the building network: Many rooftop systems sit in leased buildings where the landlord or tenant doesn’t want “solar equipment” on their LAN. Even when they say yes, corporate IT may block outbound traffic from anything they don’t manage. That leaves you blind the moment you hand over the installation.

- You only learn about faults after they’ve cost you money: An inverter that dropped offline on Tuesday, a string that’s underperforming, a CT clamp that slipped on the meter — all of these quietly drag performance below what was promised. If you find out at the end of the month instead of the same day, you’re already on the back foot with finance and the customer.

- First-line diagnostics shouldn’t require a truck roll: Too often, the only way to get real status is to put a technician in a van and send them to site to read the inverter screen and power-cycle it. That’s slow and expensive. Multiply that by 50 or 100 locations and it becomes unworkable.

- You’re expected to defend performance with evidence: Customers, auditors, and internal leadership all expect a clean history: “Here’s what the site produced, here’s when we saw a fault, here’s when it was addressed.” Guesswork and screenshots from someone’s phone are not acceptable in those conversations.

- Sites are not standardised: One site might have a tidy electrical room with structured cabling. The next might be a depot with the inverter bolted to a block wall near forklift chargers. You cannot redesign networking from scratch for each unique scenario.

Solution Overview

The solar operator standardised on a Robustel R1510 at each site as the communications and remote access point. The R1510 provides a private, policy-controlled connection from the on-site hardware to central operations — without touching the building’s LAN.

- Dedicated cellular backhaul at every site: The R1510 creates a 4G/LTE data path owned by the solar operator. There’s no dependency on tenant Wi-Fi, guest VLANs, or someone in facilities “making an exception.” That means every rooftop, warehouse, and depot can report production and alarms, even if they don’t have broadband.

- Direct link to the on-site equipment: The R1510 connects via Ethernet to the inverter, revenue meter, or PV controller. Where required, serial-connected gear can also be brought in using available interfaces or adapters. This gives remote access to operational data, fault codes, and status pages — the same information you’d normally drive out to collect.

- Secure, limited access for support teams: Only authorised users and tools are allowed to connect back through the router. You can keep access read-only if needed. That satisfies IT and compliance requirements while still letting maintenance teams investigate and take action fast.

- Portfolio view in RCMS: Every deployed R1510 registers into RCMS. Operations can see which sites are online, when each unit last checked in, signal strength, and data use. If a location suddenly stops talking, you don’t find out from a disappointed customer; you see it flagged in RCMS.

- A repeatable rollout model instead of one-off installs: The same kit — R1510 plus SIM plus known-good configuration — can be shipped, mounted, and activated in minutes. That makes it viable to scale from a handful of sites to an entire national portfolio without inventing a new process for each installation.

Expected Customer Outcomes

What success looks like for the Operator and the Integrator/Installer

For the operator:

- Live visibility of production and alarms from rooftops, warehouses, and remote depots — without relying on the landlord’s IT team.

- Fewer site visits just to “go check the inverter,” because first-line triage can be done remotely.

- Clear evidence when output drops: timestamped status, not a guess after the fact. That’s important for PPAs, ESG reporting, and internal performance guarantees.

- A rollout pattern you can repeat at every new site instead of doing engineering work for each new roof.

For the integrator:

- You’re not just selling connectivity; you’re delivering a managed, supportable layer for the whole installed base.

- RCMS keeps you in the loop post-install, so support moves from reactive (“call us when it breaks”) to proactive (“we saw site 12 go quiet at 09:14 and are already on it”).

Featured Products

Robustel R1520 Router

RCMS Cloud Device Management

Talk to an Expert

If you’re running a growing solar portfolio, the question is not “Can we see production?” It’s “Can we see it today, everywhere, without asking for access we don’t control?”

Let’s talk about giving every rooftop, warehouse, and remote depot its own reliable channel home — so you can protect yield, prove performance, and scale without adding headcount.