Secure Remote Monitoring for Oil and Gas Pipeline Distribution Sites

A Robustel Application Example

Application Example – Fast Facts

Industry

Oil, Gas and Mining, Midstream oil and gas / pipeline distribution and monitoring

Product(s)

R3000 Router; RCMS (RobustLink, RobustVPN)

Challenges

Pipeline operators need reliable, real-time visibility of remote stations: pressures, valve states, flow data, alarms across long distances. Many of these locations sit in harsh environments with no reliable fixed communications. When polling fails or a site goes dark, control room visibility is lost and compliance exposure increases.

Expected Outcomes

Give each remote pipeline site a secure, resilient communications path for SCADA and telemetry. Let operations see live data, acknowledge alarms, and act without rolling a truck to a remote valve or repeater hut. Reduce response time and maintain regulatory confidence across the network.

Pipelines are only safe if you can see them

In pipeline distribution, your world is not one building. It’s hundreds or thousands of kilometers of line, dotted with block valves, regulators, pump or booster stations, cathodic protection systems, and metering skids. Those locations are often unattended, exposed to the environment, and not always serviced by reliable wired backhaul.

Regulators expect you to know what’s happening in that network. Commercial teams expect accurate flow and volume data. Safety expects proof that alarms are acted on, not just logged.

The reality on the ground can be very different. Radios fail. Legacy RTUs drop offline. Copper gets cut. Crews don’t always know there’s a problem until someone downstream calls.

By installing a Robustel R3000 at each critical site tied into the local controller / RTU / PLC and backhauled over cellular — operators get continuous telemetry and controllable access, even in places where traditional links are unstable or expensive to expand.

Business Challenges

Pipeline distribution teams face a specific mix of operational pressure and physical reality:

- Scale: One or two bypass links can be handled manually. Fifty, a hundred, more? You need a consistent method to deploy, configure, monitor, and update field communications gear across the entire asset base.

- Limited or fragile comms at remote stations: Many valve stations, pressure control points, and custody transfer skids sit in exposed strips of land nowhere near fibre or enterprise WAN. Legacy radios have range and bandwidth limits, and fixed-line service is not always viable.

- Time and cost of physical callouts: When polling fails or data looks off, someone has to drive. That may be two hours on-road for what turns out to be a minor signal issue. Meanwhile, control has no live view of that point on the line.

- Compliance and auditability: In regulated markets, you must be able to show you knew what was happening on the network and that you responded appropriately. If a remote site goes blind, that becomes hard to defend.

- Security and access control: Operators need selective remote access to RTUs, PLCs and flow computers. But nobody wants to expose an entire pipeline control network directly to the public internet. Access has to be contained, provable, and aligned with internal policy.

Solution Overview

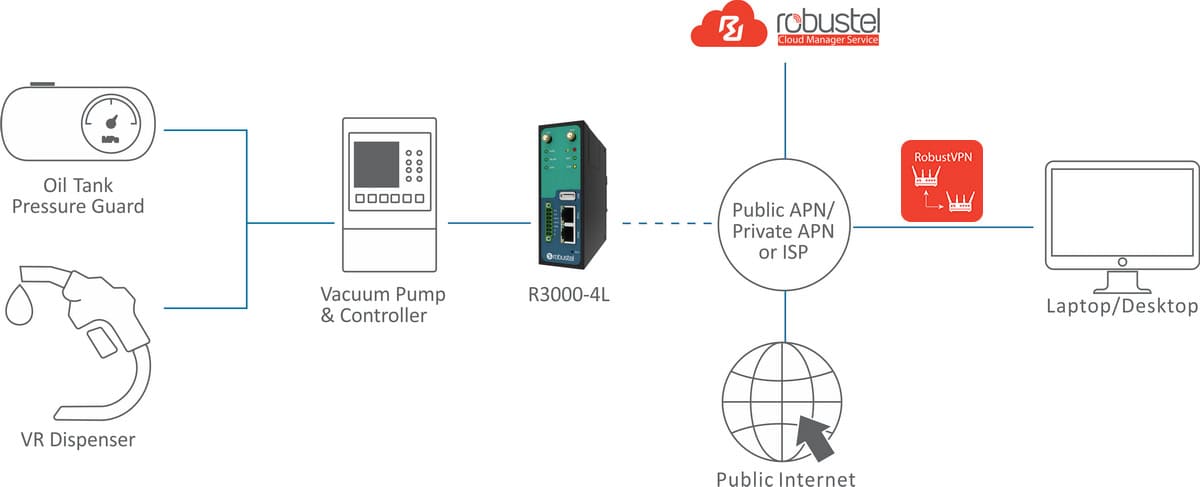

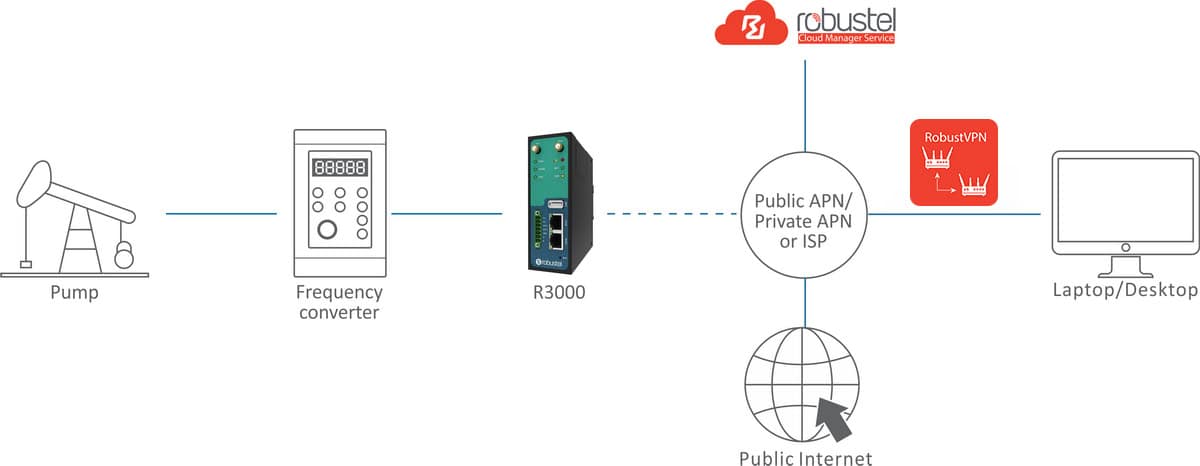

Each monitored site on the pipeline — valve station, metering skid, booster location — is equipped with a Robustel R3000. The R3000 becomes the secure communications front end for that station.

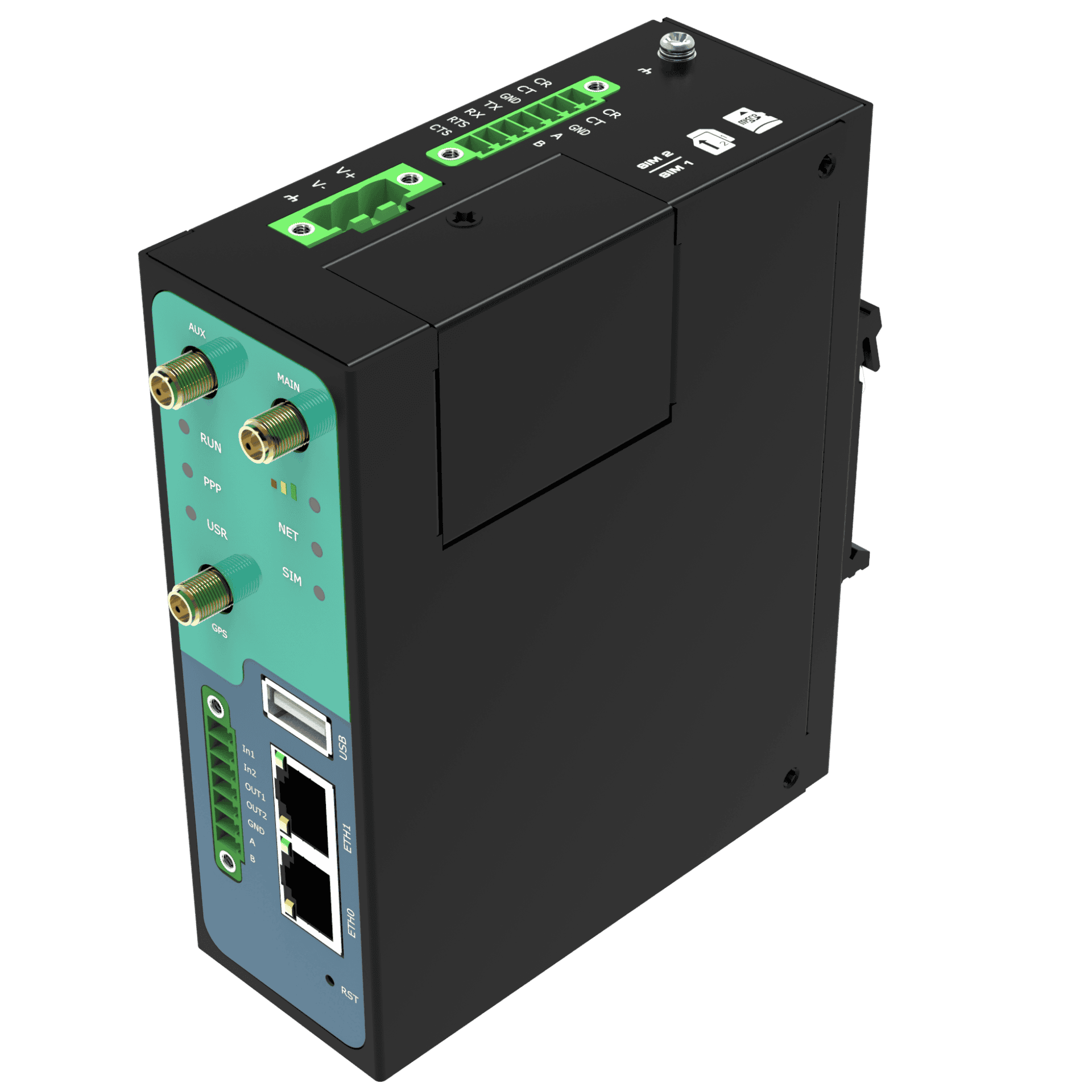

- Direct connection to local controllers The R3000 connects to the on-site PLC, RTU, or flow/pressure controller via Ethernet or serial (RS-232 / RS-485). That gives access to process values (pressure, temperature, flow), valve state, alarms, and event markers without adding a separate data logger.

- Cellular backhaul for SCADA and telemetry The R3000 provides a primary or backup WAN path using industrial-grade cellular (4G/LTE, with fallback options where coverage is weaker). This allows SCADA polling, alarm reporting, and periodic data uploads even where no wired service exists. It also means that if the primary comms link goes down, you still have visibility.

- Encrypted, scoped remote access The R3000 supports secure tunnels so that authorised personnel can remotely access the PLC or RTU for diagnostics and control. Access can be limited to that single site, time-bound, and logged. That reduces on-site dispatch while satisfying internal security expectations.

- Central oversight via RCMS All deployed R3000 units register into RCMS. From a central operations view, teams can see which stations are online, signal quality, data usage, and last contact time. They can also push configuration updates and firmware changes in a controlled way, instead of touching each site by hand.

- Built for the environment The R3000 is designed for harsh, unattended locations: wide temperature range, industrial power tolerance, DIN-rail or panel mounting, and stable performance in roadside enclosures, cabinets in easements, or small huts along the line.

This gives pipeline operators a repeatable pattern: every key site becomes visible, reachable, and supportable without waiting for a field crew to physically attend.

Expected Customer Outcomes

What success looks like for the Operator and the Service Provider

For the pipeline operator:

- You get continuous telemetry from critical points on the line, not periodic best-effort call-ins.

- You respond to alarms with context. Control can see pressure trends, valve state, and last-known values before sending anyone out.

- You reduce site visits for “is it really down?” checks. Field crews are dispatched when there’s confirmed need, not guesswork.

- You can demonstrate responsible monitoring and timely action, which supports regulatory and internal audit expectations.

For the integrator / service provider:

- You deliver a communications layer that works across distance, weather, and inconsistent infrastructure.

- You can standardize rollout: same hardware profile, same remote access method, same management story across all stations.

- You maintain ongoing service value after deployment because you can show the operator exactly what’s happening in their field assets.

In practice, this moves remote stations from “opaque risk” to “managed part of the network.”

Featured Products

Robustel R3000 Router

RCMS Cloud Device Management

Talk to an Expert

Pipelines are judged on safety, continuity, and proof of control. You can’t deliver that if your remote sites are silent.

Talk to us about giving every valve station, metering skid, and booster site its own secure communications path — so your control room sees the network as it is, not as it was the last time someone drove past.