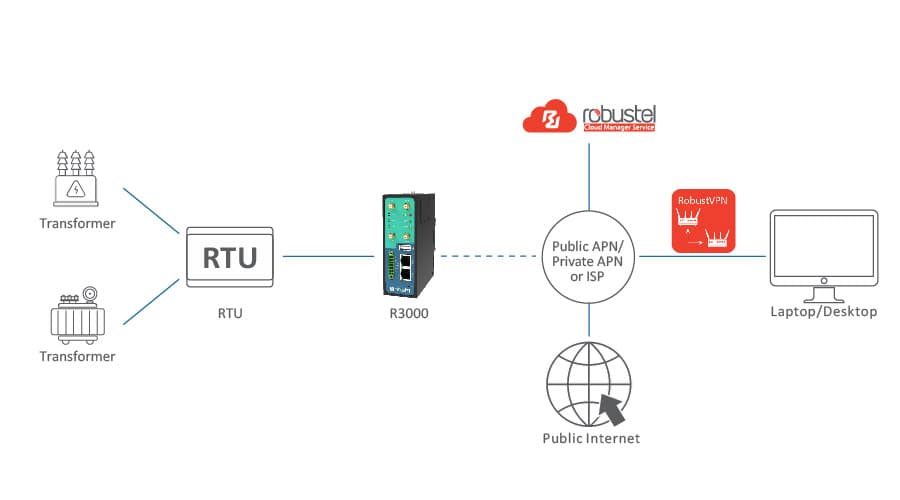

Remote Monitoring and Control for Power Distribution Assets

A Robustel Application Example

Application Example – Fast Facts

Industry

Energy & Utilities, Power distribution / electrical utilities (substations, feeders, reclosers, RMUs, FTUs)

Product(s)

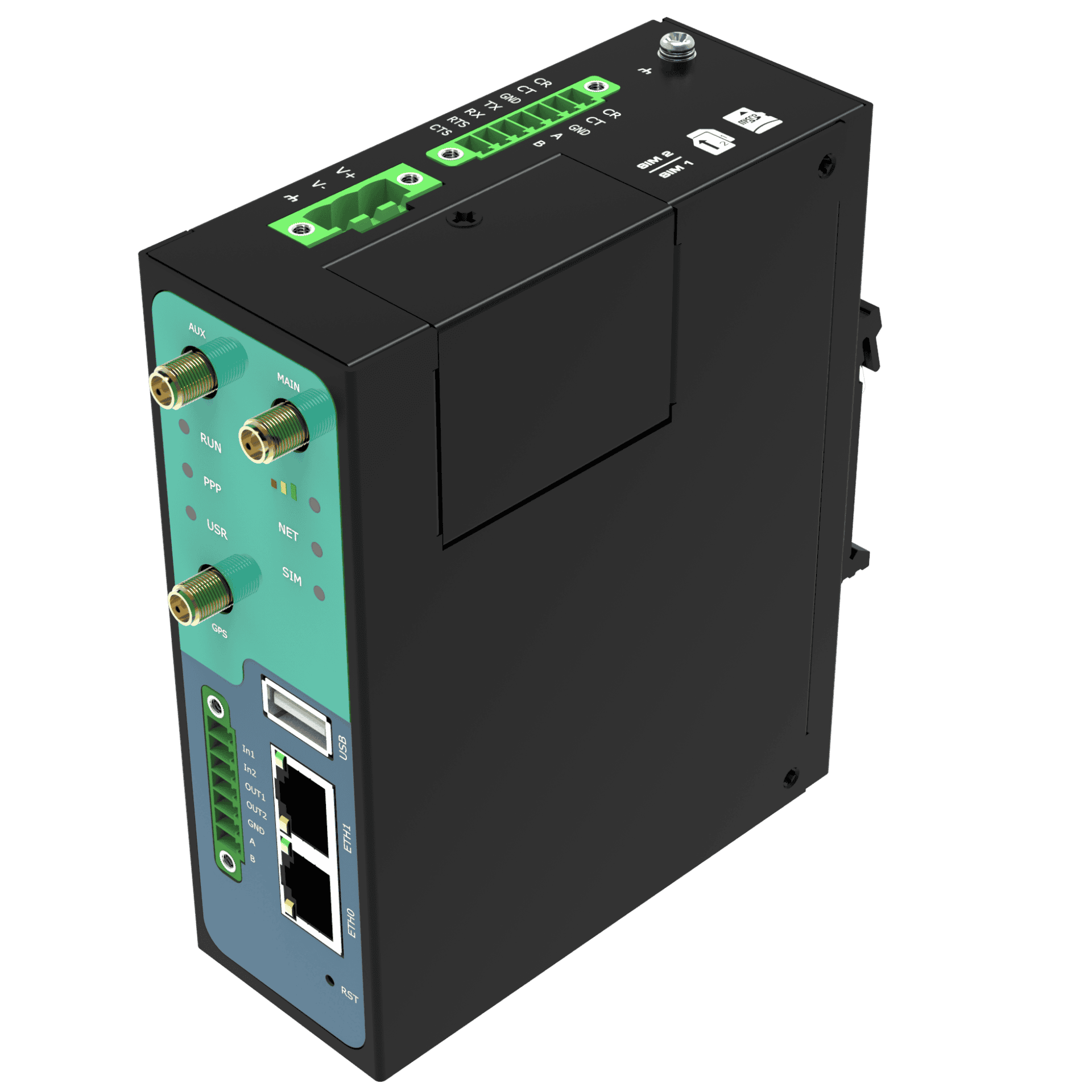

R3000 Router; RCMS (RobustLink, RobustVPN)

Challenges

Utilities need reliable, real-time visibility and control of field assets — feeder automation points, ring main units (RMUs), fault passage indicators, pole-top reclosers — across a wide, aging network. A lot of those cabinets sit in the street or out on poles, with no fibre, no copper, and limited maintenance access.

Expected Outcomes

Give each field device a hardened, secure communications path so SCADA and protection teams can see status, push commands, and confirm switching decisions without sending a crew to stand under a live line.

Restoring power is now measured in minutes, not hours

Modern networks are under constant scrutiny. Regulators track outage duration. Large customers expect evidence that you isolated and restored as fast as possible. Communities expect updates in near real time. Meanwhile, your distribution network still includes ring main units (RMUs), feeder terminal units (FTUs), reclosers, sectionalizers, and small cabinets that sit on sidewalks and roadside verges with no fibre and no spare headroom for IT gear.

When a feeder trips, the operations centre needs to know: Which section opened? Where is the fault likely located? What can we safely bring back now? Without that visibility, the default is to roll a crew, open the cabinet, read the local controller, report back on the radio, and only then start making switching decisions.

Adding a Robustel R3000 industrial cellular router at those field assets changes that dynamic. The device becomes an IP bridge for the controller in that location, so the network is no longer “silent until someone gets there.”

Business Challenges

People running distribution networks know the pain points:

- Most critical equipment is not in a substation: It’s in a box at the edge of town, on a pole, beside a carpark, or halfway down a feeder. You can’t assume fixed backhaul. Many of those sites were built long before “remotely supervised switching” was the expectation.

- Outage performance is public: Interruption metrics like SAIDI and SAIFI are watched by regulators and by large accounts. The longer you spend just working out which section failed and where it opened, the worse those numbers look.

- Sending crews isn’t just expensive — it’s exposure: Late-night storm work and live-line environments are high risk. You want people in the field only when there’s a specific task to complete, not just to confirm “what tripped where.”

- Controller diversity is real: You’re not working with one vendor and one protocol. You may have FTUs that speak serial over RS-232/RS-485, newer IEDs on Ethernet, and mixed generations of gear across the same feeder. Replacing all of it to standardise communications is rarely financially realistic.

- After-action reporting needs proof: After a fault or protection event, operations and compliance teams must be able to show who saw what, who authorised what, and in what order steps were taken to restore customers. Guesswork does not satisfy auditors.

Solution Overview

Each monitored site on the pipeline — valve station, metering skid, booster location — is equipped with a Robustel R3000. The R3000 becomes the secure Each selected field location — RMU, FTU, pole-top recloser, sectionalizer — is equipped with a Robustel R3000. That unit becomes the secure communications interface for that one asset.

- Repeatable rollout: Because the same approach works for multiple classes of plant (RMU in an urban street, recloser on a rural feeder, sectionalizer near a critical load), it becomes a playbook. You’re not engineering a brand new networking method every time you modernise a cabinet.

- Direct interface to the local controller: The R3000 connects to the controller or FTU using Ethernet or serial (RS-232 / RS-485). It can read breaker state, voltage/current information, trip indication, alarms, and other data points that operators care about. No extra specialised gateway is required inside the cabinet.

- Cellular backhaul where there is no fibre: The R3000 uses industrial 4G/LTE to create a managed, outbound link from that asset back to the utility’s network. This gives the control room near real time visibility into field conditions even in places where there is no wired service and no budget to build one.

- Controlled remote access: Access is not “open internet.” Traffic is encrypted, and permissions can be restricted to that specific device. Authorised users and systems can view status and, where policy allows, carry out switching actions remotely. That keeps operations fast while staying inside the utility’s security rules.

- Central oversight with RCMS: All deployed R3000 devices report status into RCMS. Operations sees which sites are reachable, last contact time, signal strength, data usage, and configuration. A site that quietly loses comms doesn’t stay invisible for hours. It’s flagged, and you know where to focus.

Expected Customer Outcomes

What success looks like for the Operator and the Service Provider

For the utility:

- Outage response gets faster and more defensible. Operations can see what opened and where, then make informed switching decisions without sending a crew just to gather facts.

- Fewer unnecessary truck rolls to exposed roadside assets in bad conditions.

- A clearer audit trail. You can show when the fault was detected, who authorised downstream actions, and how quickly supply was restored to each segment.

- Existing field equipment stays in service. You gain visibility and control without ripping out legacy controllers that still work.

For the integrator:

- A footprint that can expand feeder by feeder, instead of requiring a single high-risk “big bang” upgrade.

- A communications model that can be deployed across a region, not just at one flagship site.

- A management layer (RCMS) that keeps you involved after commissioning, because you’re helping the utility operate, not just dropping hardware in a cabinet.

Featured Products

Robustel R3000 Router

RCMS Cloud Device Management

Talk to an Expert

Restoration time and safety performance are now board-level metrics. You’re expected to isolate, restore, and justify every step.

Let’s talk about giving each switching point, RMU, and recloser its own managed communications path — so your operators see the real network state before they send anyone into the field.