Connectivity and Remote Service for Machine Builders & OEMs

A Robustel Application Example

Application Example – Fast Facts

Industry

Industrial IoT, Industrial equipment builders, skid/system integrators, OEM machinery suppliers

Product(s)

R3000 Router; RCMS (RobustLink, RobustVPN)

Challenges

Machines are shipped into plants, warehouses, depots and yards worldwide. Once they’re in service, the builder loses direct visibility, fault diagnosis turns into guesswork, service calls become expensive, and software changes depend on site access.

Expected Outcomes

Every shipped machine phones home securely: online status, alarms, controller data, and remote maintenance access are available without sending a technician. Support becomes predictable, service contracts become easier to enforce, and uptime becomes part of the offer.

From “ship and hope” to “ship and stay in control.”

A typical machine builder delivers a complete system PLC, drives, safety logic, HMI, enclosure then hands it over to the end customer. After that point, support becomes reactive. When something stops behaving, the first call is “your machine is down,” with almost no context: is it an actuator, a drive fault, a PLC code change, or just a tripped breaker?

By embedding connectivity at build time using the Robustel R3000, the OEM keeps a direct, secured line to that machine in the field. The machine stops being a black box. It becomes a connected asset you can diagnose, update, and defend anywhere it’s installed.

Business Challenges

For machine builders and OEMs, revenue is increasingly tied to service agreements, uptime guarantees, and fast response. But three realities get in the way:

- Once the machine is installed, it often sits behind a customer’s firewall or on an isolated OT network. Getting access to it later requires calls, paperwork, and goodwill.

- Many service tickets are trivial a sensor out of range, an inverter that tripped but you only find that out after paying to send a field engineer to site.

- Software/configuration drift is invisible. Someone on site “tweaks” PLC code or bypasses an interlock. Months later, you’re blamed for behavior you didn’t approve and can’t even see.

In short: support is blind, slow, and expensive. And the machine the customer runs is not always the machine you signed off.

Builders try to solve this by bolting on an off-the-shelf office router or asking the customer for a VPN. That doesn’t scale. It’s messy in the panel, it doesn’t survive harsh environments, and IT departments see it as intrusion.

What they actually need is a repeatable way to ship machines “service-ready”: secure remote access, data visibility, and a known-good configuration without creating a political fight with the customer’s IT and without redesigning the control cabinet every time.

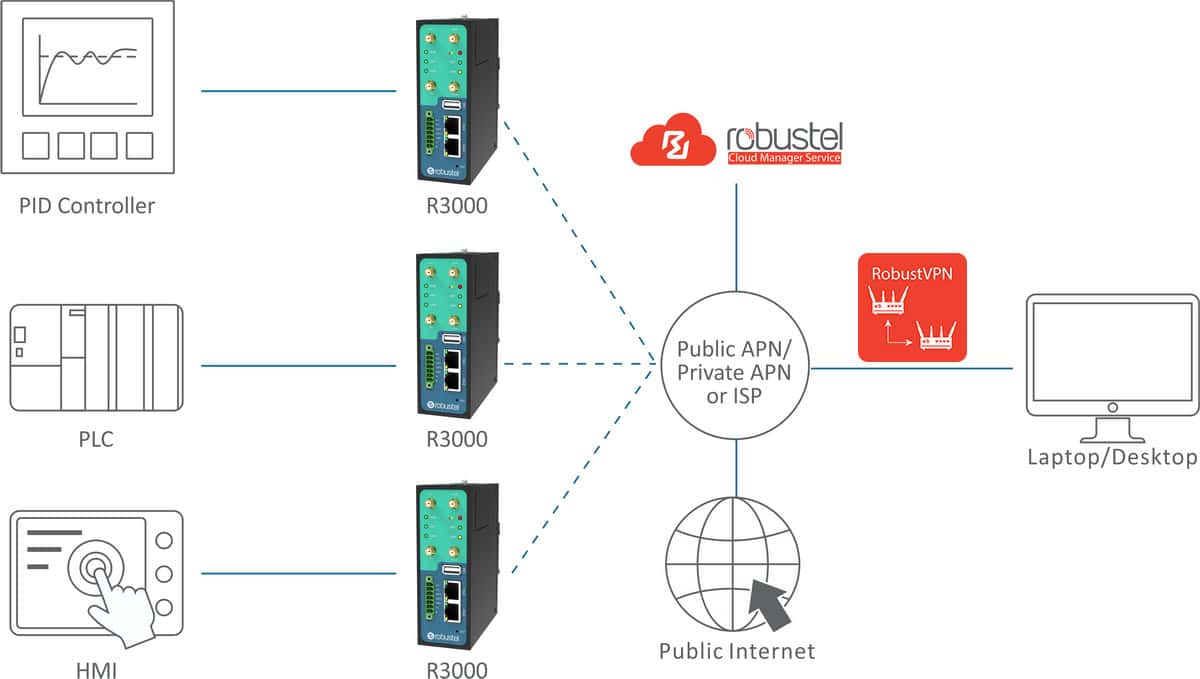

Solution Overview

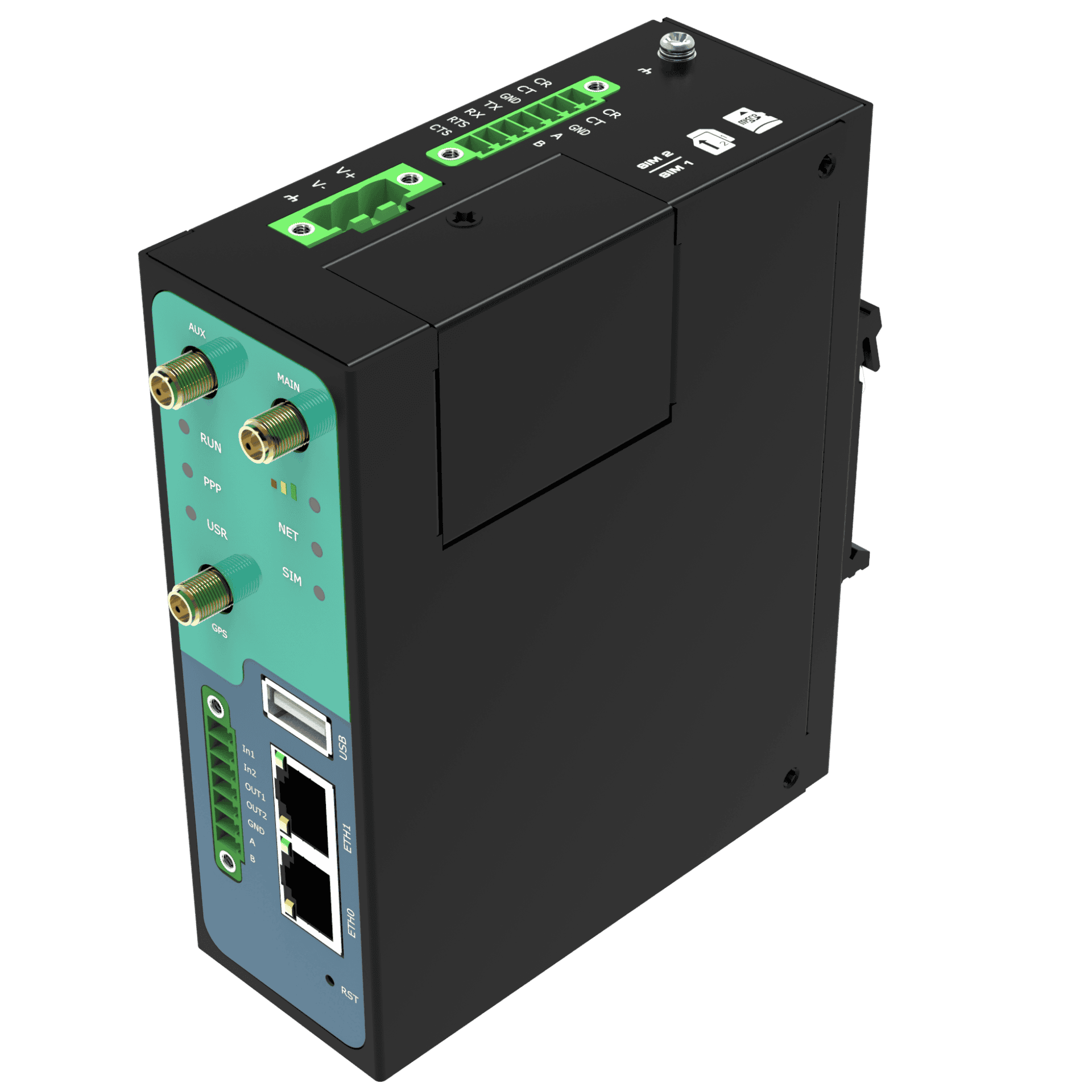

The builder standardises on the Robustel R3000 inside the control enclosure as part of the machine’s baseline design. The R3000 is treated as part of the machine, not an add-on.

- Industrial backhaul built in The R3000 provides a cellular data path (and can use Ethernet if the customer allows it) so the machine can talk to the outside world without depending on plant IT to open holes in their firewall. This lets the builder maintain access even when the machine is deployed in a different country, a different division, or at a subcontractor’s site.

- Direct interface to the control layer The R3000 connects to the PLC, drive controller, or other automation hardware via Ethernet or serial (RS-232/RS-485). That means alarms, counters, and key status values can be read directly from the controller logic the OEM supplied — not via a separate data logger or another box bolted into the panel.

- Secure remote access for support engineers A VPN tunnel (IPsec / OpenVPN / similar) is established so support staff can reach the machine as if they were standing at the panel. Access can be scoped per machine or per customer, with time-bound credentials so you’re not leaving a permanent back door open.

- Central visibility of deployed fleet Using Robustel’s cloud management platform (RCMS), the builder can see:

- Which customer machines are online

- Signal and data use (useful when dealing with roaming SIMs or remote installs)

- Basic health data and alerts that can be surfaced from the controller

- Configuration/firmware level of the router itself

- Change control you can defend Because the router is part of the standard design, things like network settings, firmware, and VPN profiles are consistent. That makes it easier to prove “we delivered it to spec,” and easier to return a machine to a known-good state if someone on site has modified it.

In other words: the builder leaves site with the machine still reachable, still intelligible, and still theirs to support.

Expected Customer Outcomes

What success looks like for the customer and the machine builder

For the machine builder / OEM:

- You can diagnose most issues before sending an engineer, and sometimes clear them remotely.

- You can see what version of logic and hardware your customer is actually running when they call for help.

- You can offer guaranteed response times with confidence, because you’re not negotiating VPN access at 2am.

- You build recurring service revenue instead of one-off emergency work.

For the end customer:

- Downtime shrinks, because fixes aren’t blocked waiting for a technician to drive or fly in.

- There’s an audit trail of what changed and when, which matters in regulated or safety-critical processes.

- They get a supplier who doesn’t just ship a machine and disappear — they get ongoing support that’s structured, not improvisational.

A connected machine feels like a supported product, not just a delivered asset.

Featured Products

Robustel R3000 Router

RCMS Cloud Device Management

Talk to an Expert

You build the machine. We make sure you can still see it, support it, and prove it’s performing wherever it ends up.

Talk to us about embedding connectivity and remote service into your next build, before it ships to site.