5G Connectivity and Remote Access for Autonomous Delivery Robots and Drones

A Robustel Application Example

Application Example – Fast Facts

Industry

Smart Cities, Smart Buildings, Logistics, Autonomous Systems

Product(s)

Robustel R5020 5G Router; RCMS (RobustLink, RobustVPN)

Challenges

Autonomous delivery robots and inspection drones need a stable, low-latency network path for supervision, telemetry, and safety handover in public or semi-public environments where WiFi is unreliable and local IT networks are off-limits.

Expected Outcomes

Each robot or drone carries its own 5G/LTE uplink, can be reached for diagnostics and control from anywhere, and can be monitored as part of a fleet — without chasing devices in the field or depending on patchy site Wi-Fi.

Always Connected Autonomy in Public Spaces

Robotic delivery carts on campuses. Inspection drones around perimeter fencing, pipe racks, or tank farms. Autonomous service units moving parts, samples, or food around hospitals and depots. These aren’t lab trials anymore — they’re now part of live operations with safety expectations, traceability requirements, and uptime targets.

The R5020 5G industrial router sits on the platform itself. It gives each robot or drone its own high-speed cellular uplink for telemetry, command traffic, and (where required) video or still image bursts. It also gives authorised staff a controlled way to connect to the unit remotely for troubleshooting, updates, or intervention. The goal is simple: keep operational control without physically standing next to the asset.

Business Challenges

Autonomous systems sound impressive in presentations. The reality is that once you deploy them in the field, you immediately run into basic operational problems that stall rollout. These are the issues most teams face before they can move from pilot to production:

- Public and campus WiFi isn’t dependable: Coverage gaps, captive portals, interference and handoffs between access points all create blind spots. A robot carrying medical samples or a drone inspecting infrastructure can’t lose comms every time it turns a corner.

- You need live situational awareness, not just delayed logs: Operations wants to see position, battery level, fault state, obstruction alerts and basic video or still captures in near real time. That’s about safety, chain of custody and SLA, not just analytics.

- Risk and compliance teams want proof of control: When a moving device shares space with staff, visitors or the public, you’re expected to show where it was, what it was doing, and that you could have stepped in if needed. “We lost the link for 90 seconds” does not go down well in incident reviews.

- Robots and drones cross network boundaries constantly: Docks, warehouses, yard space, street, campus, hospital corridor. Treating each zone as a separate WiFi network or IT domain turns into a maintenance nightmare and leaves you blind in transitions.

- Support at scale becomes the bottleneck: It’s one thing to plug in a laptop and debug a single unit. It’s another thing when you have dozens of assets and your field team spends their day driving around to pull logs. Leadership starts asking, “Is this actually supportable?”

Solution Overview

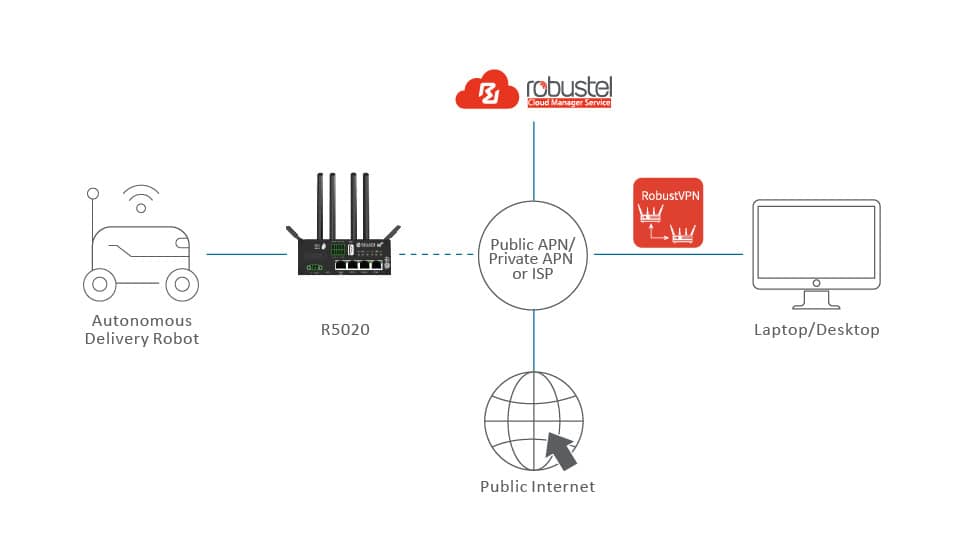

The R5020 is used as an on-board 5G/LTE router, so the connectivity and remote access story is built into the robot or drone from the start. That gives you a predictable way to supervise, update, and prove control of each asset — without relying on someone being physically on-site with it. Here’s how that works in practice:

- Dedicated 5G/LTE uplink on the platform: The R5020 sits inside the robot or drone enclosure and provides a high-throughput cellular path for telemetry, command/control data, and optional video or still images. This lets operations see the asset’s status and location live, even when it’s moving through areas with no usable Wi-Fi.

- Secure remote access for engineering and support: The router can establish an encrypted path back to the control centre. Authorised engineers can pull diagnostics, review faults, and change settings remotely, with access limited to that specific unit and for a defined window. You’re not exposing the entire fleet.

- Predictable addressing and reachability: Each asset becomes a known, reachable endpoint on the network. That means you can build dashboards, alerting workflows, and supervisory control around a consistent model instead of reinventing comms rules per site.

- Resilience when coverage changes: If 5G quality drops, the R5020 can fall back to LTE to keep the link alive. For ground robots that dock, Ethernet or Wi-Fi can take over when they’re charging or being serviced. The point is continuity — the robot or drone is still visible and still under control.

- Fleet-level oversight without field chasing: With RCMS, teams can monitor router health, confirm which assets are online, and push firmware or config changes in controlled batches. That removes a huge amount of “drive over there and plug in” work once you move beyond a handful of units.

Expected Customer Outcomes

What success looks like for the Operator and the Integrator/Installer

For the operator / fleet owner:

- Every unit is visible and reachable: You have a live path to each robot or drone over 5G/LTE for telemetry and supervision. You don’t depend on borrowed WiFi or hope that local IT will cooperate.

- Better safety and accountability: You can show where an asset was, what state it was in and that you retained the ability to intervene. That supports internal safety policy, external approval to operate, and incident review.

- Lower cost to support each deployment: When a robot faults in a corridor or a drone reports a sensor warning, technicians can inspect logs and apply changes remotely instead of physically recovering the asset every time.

- Confidence to scale beyond pilot level: Leadership sees that monitoring and support are under control. That’s what turns a good-looking demo into a signed roll out.

For the integration / robotics provider:

- A repeatable connectivity block you can ship with every unit: You’re not rebuilding networking from scratch for each customer site. You can deliver robots and drones with a known, proven 5G/LTE router already integrated.

- Less on-site babysitting: Your support team doesn’t need to physically cable into each asset to troubleshoot. You can deliver remote assistance and ongoing service contracts instead of one-off break/fix calls.

- A stronger commercial message: You’re offering more than “a robot.” You’re offering an asset your customer can supervise, audit and justify to internal stakeholders who care about safety, uptime and liability.

Featured Products

Robustel R5020 5G Router

RCMS Cloud Device Management

Talk to an Expert

If you’re under pressure to move robots or drones from “interesting pilot” to “signed-off service,” the weak point is almost always connectivity and control.

Let’s talk through how to build reliable 5G/LTE access, remote support and auditability into your platform from day one — before your operations team is asked to scale it.