Remote Water and Wastewater Monitoring Over 4G/LTE for Compliance, Uptime, and Net Zero Targets

A Robustel Application Example

Application Example – Fast Facts

Industry

Energy & Utilities, Water and Wastewater Utilities (treatment plants, pumping stations, reservoirs, remote assets)

Product(s)

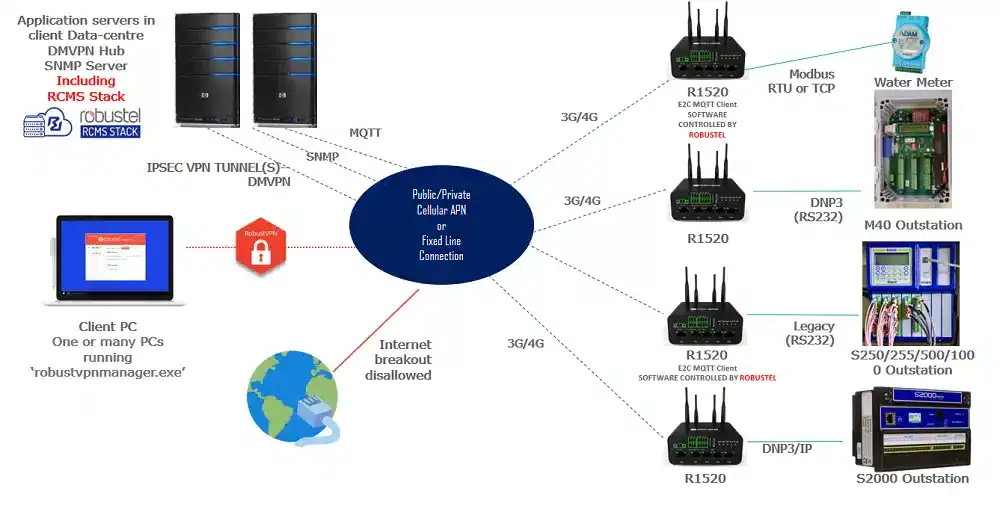

Robustel R1520 4G/LTE Router; RCMS (RobustLink, RobustVPN)

Challenges

Utilities are under pressure to prove water quality, reduce leakage and unplanned discharge, and hit long-term carbon reduction targets — all while operating widely distributed assets that are hard to reach and often have no reliable comms.

Expected Outcomes

Install an R1520 at each critical site (pumping station, treatment skid, remote tank) to collect data from PLCs, sensors, and analyzers and send it securely over 4G/LTE to central systems. Operations teams get live status, alarms, and historical evidence without constant site visits, helping them manage compliance and energy performance on the path to net zero.

Remote Monitoring and Control for Water Networks and Treatment Assets

Water authorities and industrial operators are now judged on more than simple uptime. They’re expected to keep effluent within permit limits, minimise overflow events, optimise pumping schedules to cut energy spend and emissions, and document that performance for regulators and public reporting. That expectation does not change just because an asset is 30 km away in a flood-prone field cabinet.

The reality is that many pump stations, dosing skids, and outfalls were never designed to be part of a connected system. They sit on old control panels and standalone PLCs. The only way to “check” is to drive there, open the cabinet, and read values locally. That burns hours of labour, delays response, and makes it almost impossible to prove good stewardship when something goes wrong.

By dropping in a Robustel R1520 at each remote site, utilities create a secure cellular link from local control equipment back to central SCADA, analytics, or reporting platforms. That turns a remote kiosk into a visible, managed node — with trend data, alarm visibility, and audit history you can stand behind when regulators ask what happened and when.

Business Challenges

Before talking about architecture, it’s worth calling out what utility operators and industrial water managers are actually up against day to day.

- Unmonitored assets create compliance risk: Many smaller pumping stations and wastewater nodes operate “dark.” If a level alarm trips or a blower fails, you don’t know until there’s an overflow, an odour complaint, or a call from environmental compliance. That is no longer acceptable in most regions.

- Energy use is a carbon and cost problem: Pumps and aeration systems are huge energy consumers. As utilities and industrial sites work toward 2030 and 2050 carbon targets, they need to schedule and throttle intelligently instead of running everything flat-out. You can’t optimise what you can’t see in real time.

- Roll a truck = lose half a day: Sending a technician to a remote site just to pull logs, reset a PLC, or confirm tank level does not scale, especially for networks with dozens or hundreds of dispersed assets. Travel time, access restrictions, and safety procedures all add cost.

- Data gaps weaken the story to regulators and stakeholders: When reporting to environmental agencies or corporate sustainability teams, you’re expected to show: “Here were the conditions, here’s how we responded, here’s the timestamp.” If you do not have continuous records, you’re defending reputation and compliance with guesswork.

- Existing control gear is often older, not cloud-ready: A lot of water control infrastructure runs on legacy PLCs, serial interfaces, and industrial protocols. You can’t just bolt on a generic IT modem and hope it behaves. You need something that speaks to that world and can still send usable data upstream securely.

Solution Overview

The operator installed a Robustel R1520 at each critical remote location. The R1520 interfaces directly with local PLCs, sensors, and analyzers, then backhauls operational data over 4G/LTE. RCMS provides central oversight of all deployed routers so the fleet can be managed as one system, not 200 isolated boxes.

- Industrial data capture at the edge PLC and sensor connection: The R1520 connects to local controllers (for example, level sensors, flow meters, dosing pumps, turbidity / pH analyzers in wastewater treatment) via Ethernet or serial, depending on the panel. That gives you live readings of tank level, pump run hours, discharge quality, and alarm states.

- Secure cellular uplink from hard-to-reach assets, No dependency on site IT: The R1520 provides a dedicated 4G/LTE path back to the utility’s operations environment. That means even a kiosk in a floodplain or a fenced rural bore can report condition and alarms without fibre, without Wi-Fi, and without touching a third-party network.

- Single pane for distributed assets: All deployed R1520 units register into RCMS. Central operations can immediately see which sites are online, signal strength, current data usage, and last contact time. If a remote lift station goes quiet, it shows up before it turns into a public incident.

- No blind service calls: With the router in place, authorised engineers can review status, retrieve logs, and in approved cases make safe adjustments to the local controller without physically visiting the asset. That means fewer emergency call-outs and faster stabilisation.

- Evidence to support environmental and carbon reporting: Because data is collected continuously rather than once a month, operators can demonstrate pumping behaviour, overflow prevention actions, and dosing performance. That supports both regulatory reporting (for discharge quality and overflow events) and internal emissions tracking tied to pump energy use.

Expected Customer Outcomes

What success looks like for the Building Operator and the Integrator/Installer

For the operator:

- Continuous visibility of pump stations, tanks, treatment skids, and discharge points — including those in remote or hazardous locations.

- Faster response to alarms and abnormal conditions, which helps avoid spills, fines, and reputational damage.

- Reduced field time for routine checks. Many “drive there and look at it” visits become remote diagnostics and controlled intervention.

- Better energy awareness around pumping and aeration loads, which supports both cost reduction and carbon reduction targets.

- A defensible record of performance and response when regulators or local authorities ask what happened.

For and the integration/installation partner:

- A repeatable pattern: one R1520 per remote asset, centrally managed through RCMS.

- Ongoing operational value, not just a one-time hardware sale, because the utility now depends on that data stream to run and report.

Featured Products

Robustel R1520 Router

RCMS Cloud Device Management

Talk to an Expert

If you run pumps, lift stations, dosing skids, or treatment assets that nobody sees until there’s a problem, you already know the risk sits in the quiet places.

Let’s talk about giving those remote sites a reliable voice, so you can respond earlier, prove performance when challenged, and move toward your environmental and carbon commitments without adding more people to the field.