LoRaWAN Monitoring for Solar Power Plants and Battery Storage Sites

A Robustel Application Example

Application Example – Fast Facts

Industry

Utility-scale solar farms, distributed solar plants, and hybrid solar + storage sites

Product(s)

Robustel LG5100 LoRaWAN & Edge Computing Gateway; RCMS (RobustLink, RobustVPN)

Challenges

Large solar sites spread across wide ground need real-time performance and fault data from inverters, combiner boxes, trackers, weather stations, and storage systems. Many of those assets sit far from fibre or Ethernet, run on low power, and can’t justify a full industrial router at every point.

Expected Outcomes

Use long range wireless sensing (LoRaWAN) to collect field data across the site, land it locally at the LG5100 gateway, and push clean telemetry upstream over cellular or Ethernet. Operations gets visibility, alarm reporting, and proof of production without sending people into the field with a laptop.

Solar operators are judged on production, warranty compliance, and uptime, not just installed megawatts

A solar plant is not one box. It is rows of panels, combiner boxes, DC strings, trackers, batteries, weather stations and metering points scattered over hundreds of metres or more. When output drops on one string or a combiner overheats, you need to know quickly, not at the next manual walk-down.

The problem is distance. Pulling cable to every sensor is expensive. Putting a full cellular router at every pad is not realistic. Many sensors are low power and sit in enclosures that were never designed for traditional networking.

By placing a Robustel LG5100 LoRaWAN & Edge Computing Gateway on site, you create a local collection point. Low power LoRaWAN sensors report status (current, voltage, temperature, tilt, irradiance, battery state of charge, cabinet door open, etc.) over long range wireless. The LG5100 receives that data, applies basic logic and filtering at the edge, and then forwards only what matters to SCADA, the energy management system, or the cloud. You get a live picture of health and yield without wiring every corner of the farm.

Business Challenges

Before we talk about architecture, it’s worth stating the day-to-day reality for anyone running solar or storage assets at scale.

- Large physical footprint, no affordable cabling: Solar infrastructure is spread across long runs and open ground. Pulling Ethernet or fibre to every combiner box, tracker, or weather mast is expensive and slow. That leaves critical parts of the site effectively invisible between manual inspections.

- Underperformance costs money instantly: When output drops on one block, you feel it in production reporting, PPA commitments, and warranty claims. Waiting hours to find out that a single combiner overheated or a tracker stalled means lost generation you cannot bill.

- Most field devices are low power and sealed: Trackers, string monitors, cabinet temperature probes, and local weather instruments often run on minimal power and sit in tight housings. They cannot host a traditional router, and they cannot sustain chatty polling.

- Manual walk-downs don’t scale past a few MW: Sending technicians across a site with handheld tools to locate “the hot box” or “the dead string” is labour-heavy, risky in high heat, and reactive. By the time you’ve found the failure, you’ve already lost energy.

- The control room needs usable signals, not raw noise: Operations teams want clear alarms and trend data that can drop into SCADA, EMS, or analytics platforms. They do not want a flood of unprocessed sensor chatter. They need structured data they can trust in an audit.

Solution Overview

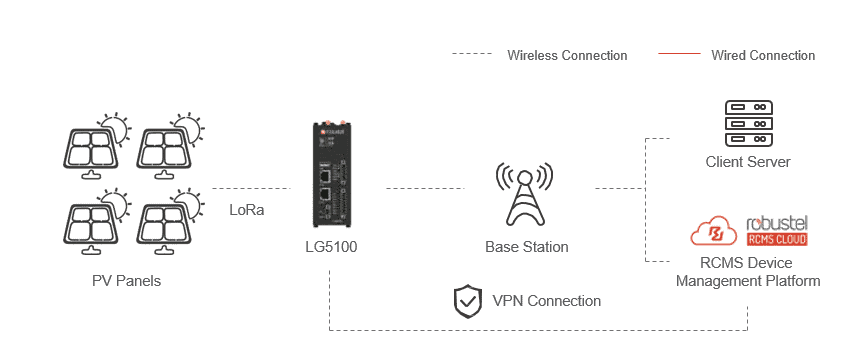

The solar operator deployed Robustel LG5100 gateways across the site as local collection and forwarding points. Each gateway acts as both a LoRaWAN hub and an edge processor, then uses cellular or Ethernet backhaul to relay structured data upstream. RCMS provides central oversight of those gateways across all blocks.

- LoRaWAN for long range, low power sensing: The LG5100 serves as the on-site LoRaWAN gateway. Low power LoRaWAN sensors are installed on inverters, combiner boxes, trackers, metering points, and environmental stations. They send live measurements: current, voltage, panel tilt, cabinet temp, state of charge — over long range wireless without needing new trenching or mains power at each point.

- Edge intelligence in the gateway: The LG5100 is not only a radio bridge. It runs an edge computing environment so basic logic can execute locally. That includes threshold checks (over-temp, abnormal string output), simple correlation, and pre-formatting into structured records. You only forward what matters, not every raw register read.

- Backhaul over cellular or Ethernet: The gateway then publishes the filtered data to the operator’s SCADA, EMS, historian, or monitoring platform using either 4G/LTE or Ethernet where it’s available. This means you don’t need a heavy industrial router at every sensor cluster. One LG5100 can represent an entire block.

- RCMS for fleet visibility and control: All LG5100 gateways are registered into RCMS. Operations can see whether each site or block is online, check last contact time, cellular signal, data usage, and config version, and push updates remotely. If a gateway goes quiet, you know before the gap shows up in your production report.

- Repeatable pattern across multiple plants: Because the design is consistent LoRaWAN sensors in the field, LG5100 as the collection point, RCMS for oversight, you can roll it out plant by plant, phase by phase, without re-engineering your telemetry approach each time.

Expected Customer Outcomes

What success looks like for the Operator and the Service Provider

For the solar operator:

- Faster detection of weak or failed strings, overheating combiner boxes, stalled trackers, and abnormal inverter behaviour.

- Fewer blind spots across wide ground. Even remote corners of the site are reporting in.

- Lower field exposure. Technicians go straight to the fault instead of searching for it in 40°C heat.

- A recorded view of performance and alarms that supports warranty claims, asset reporting, and investor expectations.

For service partner:

- A repeatable, supportable telemetry model you can deploy across multiple farms, not just one showcase project.

- Ongoing operational value because RCMS keeps those gateways visible long after commissioning.

- A credible story for stakeholders: this is production monitoring for utility-scale solar, not an experiment.

Featured Products

Robustel LG5100 LoRaWAN Gateway

RCMS Cloud Device Management

Talk to an Expert

Solar and storage assets are now monitored like revenue infrastructure, not static installs. You’re expected to catch issues early, protect field teams, and back every claim with data.

Let’s discuss how a LoRaWAN + edge gateway design can give you full-site visibility without pulling fibre to every combiner box.