Maritime Fuel-Oil Data Collection for IMO CII Reporting

A Robustel Application Example

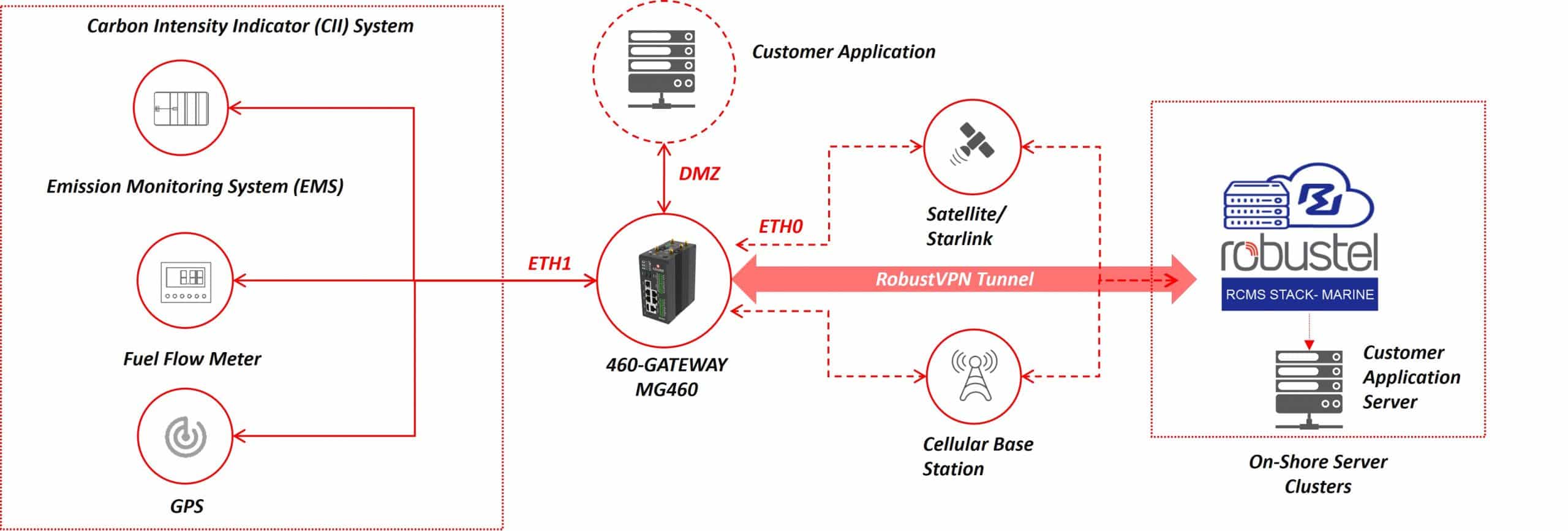

Application Example – Fast Facts

Industry

Maritime (commercial vessels)

Product(s)

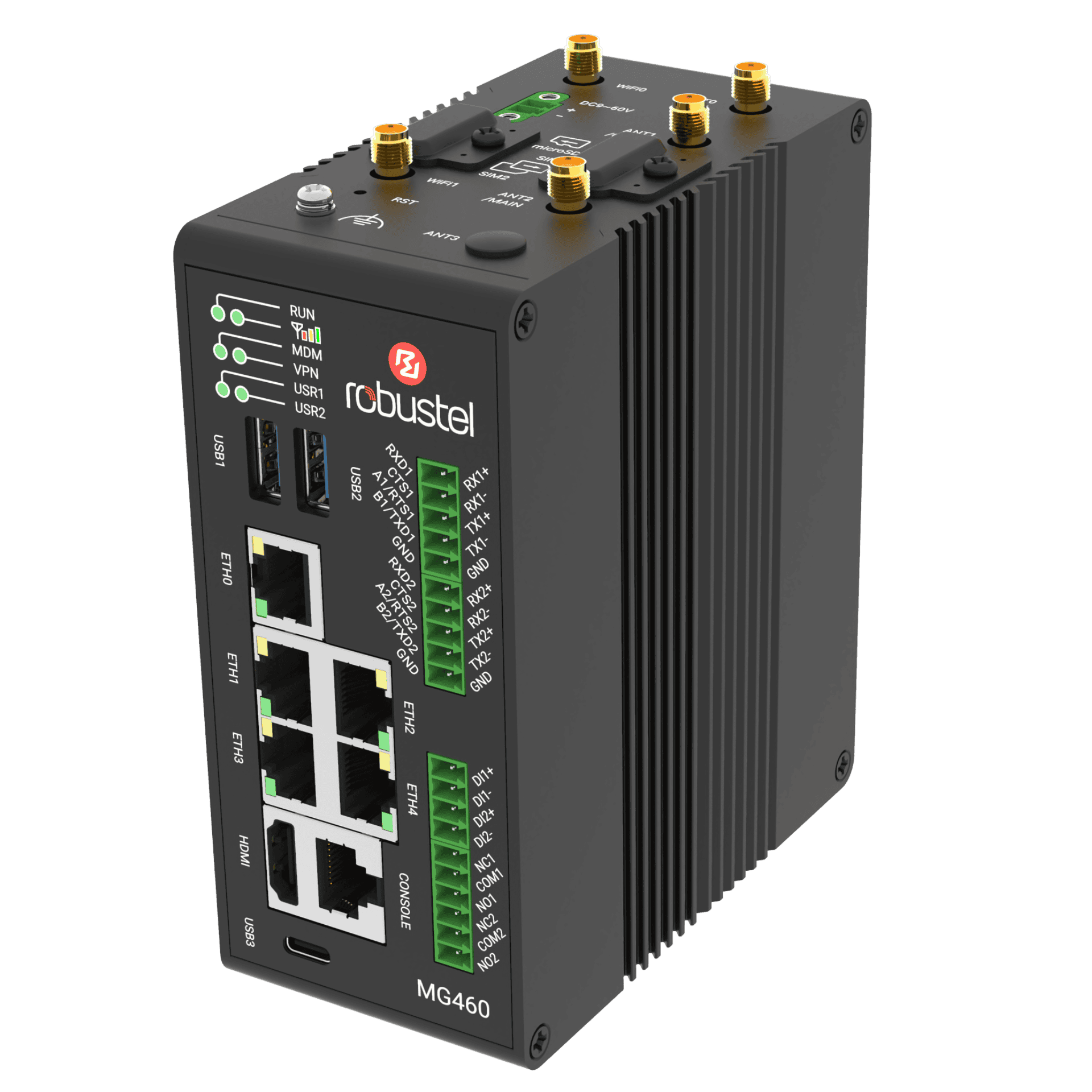

MG460 gateway with MG Core; RCMS (RobustLink, RobustVPN); optional Edge data handling where appropriate

Challenges

Fragmented fuel data, manual noon reports, audit risk, inconsistent vessel networks, limited vendor access control

Expected Outcomes

Trusted, timestamped fuel-oil records to shore; IMO CII and IMO DCS-ready data; controlled remote access; shorter audits

From noon reports to audit-ready fuel records

Ship operators must evidence fuel-oil consumption and operational data to meet the International Maritime Organization (IMO) Carbon Intensity Indicator (CII) and the IMO Data Collection System (DCS) for fuel-oil consumption. On board, fuel information lives in separate systems—flow meters, tank level gauges, engine and boiler controllers, bridge logs—while shore teams need a reliable, secure way to collect this data, preserve its integrity, and deliver it to reporting platforms without adding PCs and ad-hoc networks to the vessel.

Business Challenges

Data integrity and auditability: Manual transfers and spreadsheets create gaps, version drift, and weak audit trails for IMO CII and IMO DCS submissions.

Network segmentation: Bridge, OT, maintenance, and crew networks must be separated to align with IACS UR E26/E27 objectives and IEC 61162-460 network design principles.

Heterogeneous equipment: Different meters and controllers speak different protocols and are maintained by different vendors.

Limited vendor access: Service partners need occasional access, but operators must keep strict control and clear logs.

Lifecycle management: Vessels join and leave routes; software and policies must be deployed and updated consistently across the fleet.

Solution Overview

Here’s how we turn reporting goals into an operational pattern your crews can live with. We start with a compliant gateway foundation the MG460 Gateway running MG Core then add the minimum services needed to collect fuel-oil data from approved shipboard systems and deliver it shore-side in a way that suits IMO Carbon Intensity Indicator (CII) and IMO Data Collection System (DCS) workflows. The result is a standardized, auditable approach you can roll out across vessels without adding fragile PCs or one-off integrations.

- Compliant gateway foundation: Deploy MG460 gateways running MG Core to enforce segmentation, least-privilege access, signed updates, and clear logging supporting IACS UR E26/E27 and IEC 61162-460 aligned designs.

- Data collection to shore: Where appropriate, read fuel-related values from approved onboard systems (e.g., flow-meter head units or tank-level controllers) and forward timestamped, tamper-evident records to shore over a single, policy-controlled outbound link suitable for IMO CII and IMO DCS workflows.

- Controlled remote access: Use RobustVPN to grant time-boxed, role-based access for meter and engine vendors without exposing the vessel LAN. All actions are logged for audit.

- Fleet operations at scale: Use RCMS to onboard gateways with Zero-Touch, apply standard templates per vessel class, roll out firmware in rings, and monitor configuration state, uptime, and data use.

Note: Specific data sources and interfaces are defined per equipment list and class-approved integration plan. The gateway does not alter certified instrumentation; it transports and protects data.

Expected Customer Outcomes

You get trustworthy, timestamped fuel-oil data to shore for IMO Carbon Intensity Indicator (CII) and IMO Data Collection System (DCS) reporting, with clean network segmentation and controlled, auditable access without adding fragile onboard PCs. The result is higher uptime, lower support effort, and shorter audits across every vessel you roll out.

- CII/DCS-ready data, consistently: Timestamps, device identity, and configuration history provide a trustworthy record from vessel to shore for IMO CII and IMO DCS reporting.

- Clean segregation: Bridge/OT networks remain separate from crew and guest access, supporting your IACS/IEC design objectives.

- Lower support burden: Standardized builds, controlled vendor access, and remote diagnostics reduce time in port and callouts at sea.

- Audit confidence: Signed updates, activity logs, and a clear change history shorten evidence gathering for inspections and renewals.

Featured Products

Robustel MG460 Gateway

MG Core Operating System

RCMS Cloud Device Management

Talk to an Expert

Every vessel mix is different. Share your route profile, equipment list, and CII/DCS workflow and we’ll design a compliant gateway pattern and rollout plan that fits your fleet.