Traditional wired connections in factories are gradually being replaced by wireless networks via industrial robotic arms. Improved safety and cost-cutting are the driving forces behind this change. Due to fewer tangled cables, wireless networks pose less safety risks and decrease the expenditures associated with significant wiring. Besides, consistent, low-latency transmission is required for the massive volume of data created by robotic arms, which is frequently difficult to do using traditional means.

Moreover, conventional manufacturing Local Area Networks (LANs) can increase expenses by limiting data monitoring to certain areas and making remote maintenance more difficult. To address these issues, Robustel has created an industrial robot networking solution.

The Solution: Industrial Robot Networking Solution

Maximizing productivity and maintenance capabilities, this industrial system seamlessly integrates robotic arms with platforms for device and operational management.

Through a serial connector, the Robustel IIoT Gateway receives data from the robotic arm. The operation platform and Robustel RCMS device management platform are then accessed by this gateway via a private 5G high-speed network. Real-time operational data from the robotic arm is continuously collected and reported as a consequence.

Key Features:

- High-Speed Connectivity. To ensure quick and dependable data transfer, the solution provides a range of customizable connectivity options, such as 5G/4G/3G cellular networks, Wi-Fi, wired connections, and link management.

- Real-time Data Collection. Terminal data is continuously collected and uploaded using the Edge2Cloud applications and the RobustOS Pro operating system. This enhances the ability of administrators to make decisions and perform maintenance by enabling them to access real-time on-site data remotely through the cloud platform.

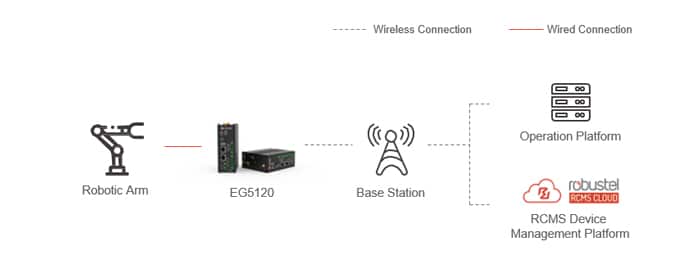

Topology

Robustel's Industrial Robot Networking Solution makes use of the EG5120 cellular router to give industrial robots smooth remote monitoring and control by establishing a reliable and secure wireless link between robotic arms and a centralized cloud management platform (RCMS) via a base station.

The Advantages: Why Use Robustel Devices for Your Industrial Robot Networking Solution

In the demanding world of industrial robotics, reliable and efficient networking solutions are essential. Robustel devices offer a unique blend of features that make them an ideal choice for optimizing your industrial robot networking solution.

- Unique (E2C) Edge2Cloud Software. Robustel's unique Edge2Cloud (E2C) software empowers your IoT Gateway for seamless Modbus to Cloud connectivity and advanced edge computing capabilities.

- Support for Custom Applications. Customize your applications effortlessly with Robustel's RobustOS and RobustOS Pro software development kits (SDKs), optimizing router resources and eliminating the need for costly embedded PCs.

- Supports Docker. Leverage Robustel's Docker containerization to smoothly port your software from other platforms to the EG5000 series Gateways, ensuring compatibility and ease of deployment.

- Flash Manager Tool. Robustel's EG5000 series gateways feature a Flash Manager tool, specifically designed to mitigate wear and tear on NAND Flash memory, safeguarding your critical data and applications.

Experience the future of industrial robot networking with Robustel's cutting-edge technology and adaptable solutions.