For uninterrupted operations in high-tech factory environments, reliable communication between Medium Voltage (MV) switchgear and the Supervisory Control and Data Acquisition (SCADA) system is essential.

This case study details the implementation of a robust communication solution, using the Robustel R1520-4L industrial cellular router, to ensure stable data transfer from Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) within the MV switchgear to the SCADA system.

The solution emphasizes critical features including dual SIM redundancy, multiple Ethernet ports, and secure 4G remote access.

Project Overview:

To ensure smooth system operations in high-technology factory applications, a robust communication system is essential. Within this system, uninterrupted and stable data transfer from field devices to the SCADA system is critical.

Vacuum circuit breakers (VCBs), crucial for maintaining safe and continuous power management on production lines, operate in high-voltage electrical circuits by extinguishing arc formation in a vacuum environment, reliably and rapidly cutting off electrical current, thereby preventing potential issues.

This project aimed to enable communication with the SCADA system using data obtained from PLC and HMI end devices located within the Medium Voltage (MV) switchgear of a high-technology factory.

The factory's MV switchgear communication system necessitated the deployment of wireless communication equipment to establish a link with the SCADA system. To guarantee uninterrupted communication, an industrial router with stable 4G wireless connectivity was chosen. Dual SIM support was crucial for redundancy, safeguarding against data loss when collecting data from devices in various factory locations.

As the data gathered from PLCs and HMIs within the MV switchgear was entirely Ethernet-based, the communication system device required a substantial number of Ethernet ports.

The Solution: Robustel Industrial Router for Stable 4G Wireless Connectivity

To address the critical communication needs of the factory's MV switchgear system, the Robustel R1520-4L industrial cellular router was selected as the core connectivity solution.

This decision was driven by the device's comprehensive feature set, tailored to ensure uninterrupted data flow and robust network resilience. The following features proved particularly influential:

Enhanced Redundancy with Dual SIM Card Support:

Given the potential for signal fluctuations and network outages in remote or challenging factory locations, dual SIM card support was paramount. This feature provides seamless failover, ensuring continuous connectivity by automatically switching to a secondary SIM card if the primary connection is lost. This redundancy is crucial for maintaining real-time data transmission from the MV switchgear to the SCADA system, minimizing downtime and potential production disruptions.

Versatile Connectivity with 5 Ethernet Ports

The MV switchgear system, utilizing numerous Ethernet-based PLCs and HMIs, was effectively supported by the R1520-4L's five Ethernet ports. This ensured seamless connectivity, streamlining data aggregation and transmission. Consequently, additional network switches were unnecessary, simplifying the network architecture and minimizing potential points of failure.

Reliable and Stable Industrial-Grade 4G Connectivity

To ensure consistent data transfer to the SCADA system, the project required a stable and reliable wireless connection. The R1520-4L's industrial-grade 4G capabilities provided robust connectivity, effectively mitigating potential electromagnetic interference and signal challenges. This resulted in consistent real-time data transfer.

Secure Remote Access via VPN over 4G

A key requirement was remote access for monitoring and troubleshooting. The R1520-4L's integrated VPN over 4G enabled secure remote access, allowing engineers to diagnose and resolve issues without on-site visits. This significantly reduced response times and operational costs.

By using the Robustel R1520-4L's advanced features, coupled with GSL's expert support, the factory successfully implemented a reliable and resilient communication system for its MV switchgear, ensuring continuous data flow and enhanced operational efficiency.

Topology

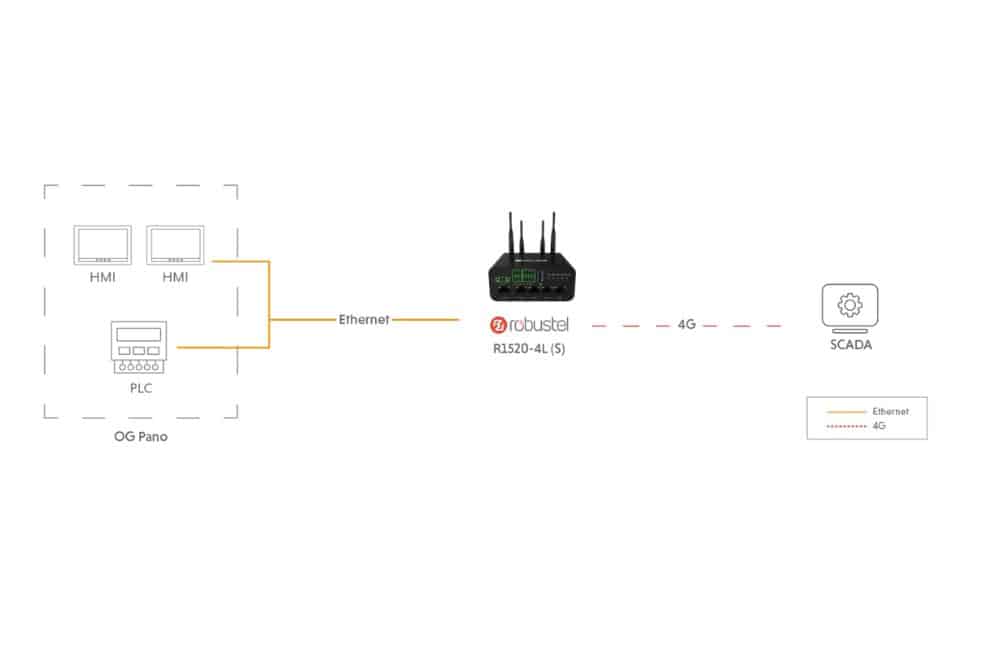

The diagram below illustrates a common topology for a Factory MV Switchgear Communication System, showcasing the interconnection of Human-Machine Interfaces (HMIs), Programmable Logic Controllers (PLCs), and a Supervisory Control and Data Acquisition (SCADA) system.

The Robustel R1520-4L(S) 4G router acts as a crucial bridge, enabling remote access and data transmission between the local network and the SCADA system, ensuring efficient monitoring and control of switchgear operations.

Conclusion

The Robustel R1520-4L industrial router has been instrumental in improving the communication system for the factory's MV switchgear. By ensuring reliable data transfer from field devices to the SCADA system, through its dual SIM support, multiple Ethernet ports, and robust 4G connectivity, it enables real-time monitoring, remote access, and efficient maintenance, resulting in improved operational efficiency and reduced downtime.

To learn more about Robustel's industrial IoT routers and how they can enhance your factory's communication system, contact Robustel today!