Leading worldwide provider of intelligent fluid flow and control systems, Armstrong Fluid Technology uses wireless technology in its smart pumps, VFDs, and building management systems to improve performance and efficiency.

This article outlines how the Robustel R2010 offers dependable wireless connection, safe remote access, and real-time data monitoring, all of which eventually helps Armstrong's system's operational efficiency and predictive maintenance capacity to improve.

Who is Armstrong Fluid Technology?

Armstrong Fluid Technology is focused on offering complete fluid flow and control solutions worldwide. Their product line consists of a broad spectrum of tools, including pumps, meant for various uses, including HVAC systems, plumbing, and industrial operations.

Moreover, they provide heat exchangers to help different systems effectively transmit thermal energy. Armstrong Fluid Technology combines cutting-edge controls for maximum efficiency and management to optimize fluid system performance using smart technologies.

How Robustel R2010 to be used in Armstrong

Effectively integrated with Armstrong Fluid Technology systems, the Robustel R2010 is a flexible industrial 4G LTE router improving communication and data management. Here how it could be applied:

1. Reliable Wireless Communication

4G LTE Connectivity: The R2010 has fast 4G LTE connectivity, which lets Armstrong sensors and devices provide real-time data to cloud platforms or central management systems.

2. Data Collection and Transmission

- Sensor Integration: The router can connect to multiple sensors (temperature, pressure, flow, etc.), facilitating the aggregation of data for comprehensive system monitoring.

- Real-Time Monitoring: Continuous data transmission supports real-time monitoring of system performance, which is essential for predictive maintenance.

3. Secure Remote Access

- VPN Support: The R2010 supports Virtual Private Network (VPN) connections, allowing secure remote access for operators and technicians to monitor and manage systems.

- Firewall and Security Features: Built-in security features protect against unauthorized access, ensuring data integrity and system security.

4. Network Management

- Failover Capabilities: The R2010 can automatically switch between primary and backup networks (e.g., cellular and Ethernet) to maintain uninterrupted connectivity.

- Web Interface: It includes a user-friendly web interface for easy configuration, monitoring, and management of the router settings.

5. Alerts and Notifications

- Configurable Alerts: The router can facilitate alerts for system performance issues, enabling operators to respond proactively to potential problems.

6. IoT Compatibility

- Integration with IoT Devices: The R2010 is compatible with IoT technologies, allowing it to work seamlessly with Armstrong’s smart sensors and devices for enhanced data collection and analysis.

Users of Armstrong Fluid Technology systems can increase wireless connection dependability, remote management capability, and data transfer efficiency by applying the Robustel R2010, therefore guaranteeing effective monitoring and predictive maintenance. This integration helps system performance and general operational effectiveness.

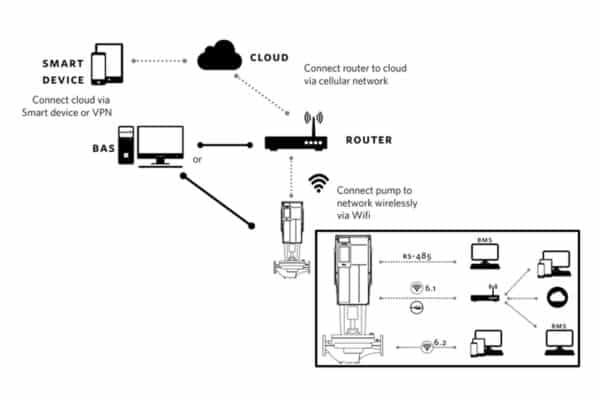

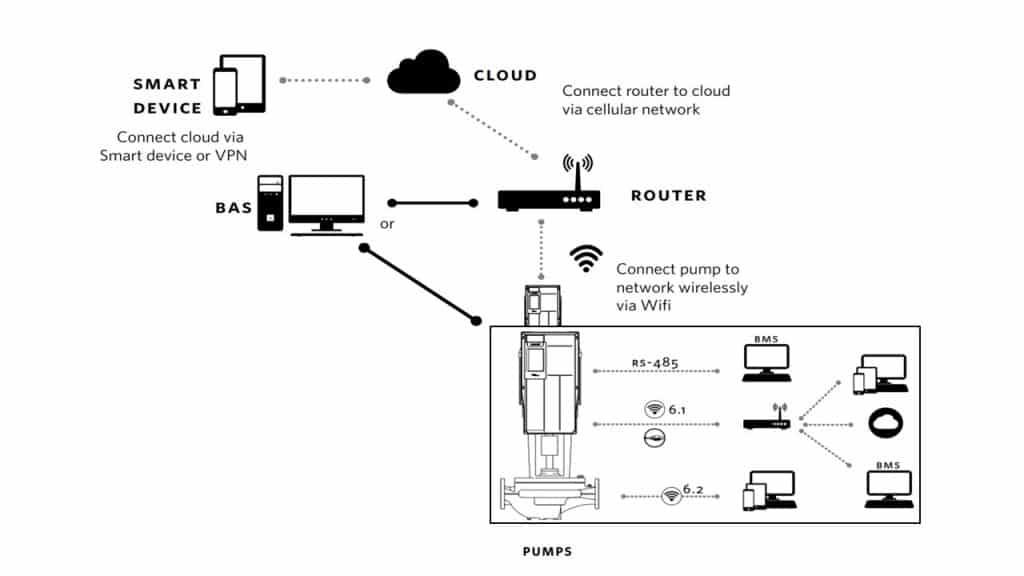

Topology

The diagram below illustrates a typical network topology for integrating smart devices, building automation systems (BAS), and building management systems (BMS) with cloud connectivity for remote monitoring and control of a pump system.

What is the benefit to use R2010 in Armstrong System?

Using the Robustel R2010 in Armstrong Fluid Technology systems offers several benefits, particularly in enhancing connectivity, data management, and overall system efficiency. Here are the key advantages:

1. Reliable Connectivity

Strong, fast internet access via 4G LTE guarantees continuous data flow from sensors and devices in far-off or difficult areas.

2. Real-Time Data Monitoring

Real-time monitoring of system performance made possible by immediate access to data lets one make quick decisions and intervene as necessary.

3. Enhanced Remote Management

By means of safe VPN connections, secure remote access helps to administer and monitor systems, so enhancing operational flexibility.

4. Integration with IoT Devices

Works perfectly with many Armstrong IoT devices and sensors, therefore producing a coherent data collecting and processing solution.

5. Improved Predictive Maintenance

Data aggregation gathers and distributes data from several sensors to assist predictive maintenance plans that save downtime and repair costs.

6. User-Friendly Interface

The web-based interface makes setup and continuous management easier, so accessible for operators.

7. Failover Capabilities

Essential for preserving system performance, automatic switching between main and backup connections guarantees continuous service.

8. Scalability

The R2010 fits for expanding uses or extra devices since it can quickly adjust to rising system needs.

9. Cost-Effective Operation

Promoting effective monitoring and maintenance helps to reduce the general running expenses related to system breakdowns and repairs.

10. Enhanced Security Features

Built-in security features including firewalls and encryption help to safeguard private information and guarantee industry standards' compliance.

Conclusion

By integrating the Robustel R2010 into Armstrong systems, maintenance strategies, operational efficiency, and communication are much improved, which finally results in better performance and dependability in fluid management and HVAC applications.